Imeeli: sale@hebeidisha.com

Imeeli: sale@hebeidisha.com

Tẹli: +86 13315186550

Tẹli: +86 13315186550

- Afirika

- Ede Albania

- Amharic

- Larubawa

- Ara Armenia

- Azerbaijan

- Basque

- Belarusian

- Ede Bengali

- Ede Bosnia

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Ede Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonia

- Finnish

- Faranse

- Frisia

- Galician

- Georgian

- Jẹmánì

- Giriki

- Gujarati

- Haitian Creole

- hausa

- ara ilu Hawaiani

- Heberu

- Bẹẹkọ

- Miao

- Ede Hungarian

- Icelandic

- igbo

- Ede Indonesian

- Irish

- Itali

- Japanese

- Javanese

- Kannada

- Kasakh

- Khmer

- Ede Rwandan

- Korean

- Kurdish

- Kirgisi

- TB

- Latin

- Latvia

- Lithuania

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Èdè Malta

- Maori

- Marathi

- Mongolian

- Mianma

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scotland Gaelic

- Ede Serbia

- English

- Shona

- Sindhi

- Sinhala

- Slovakia

- Slovenia

- Somali

- Ede Sipeeni

- Ede Sundan

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Tọki

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbekisi

- Vietnamese

- Welsh

- Egba Mi O

- Yiddish

- Yoruba

- Zulu

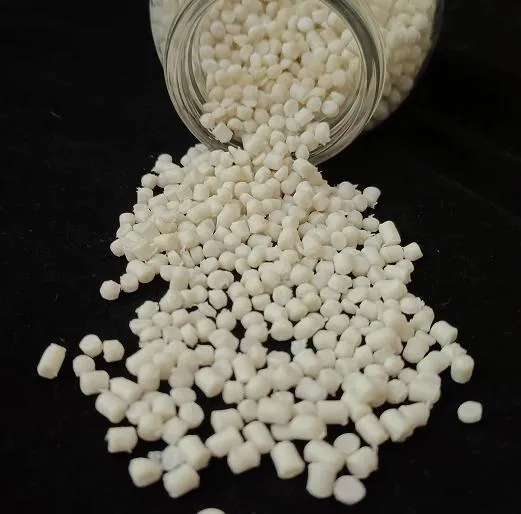

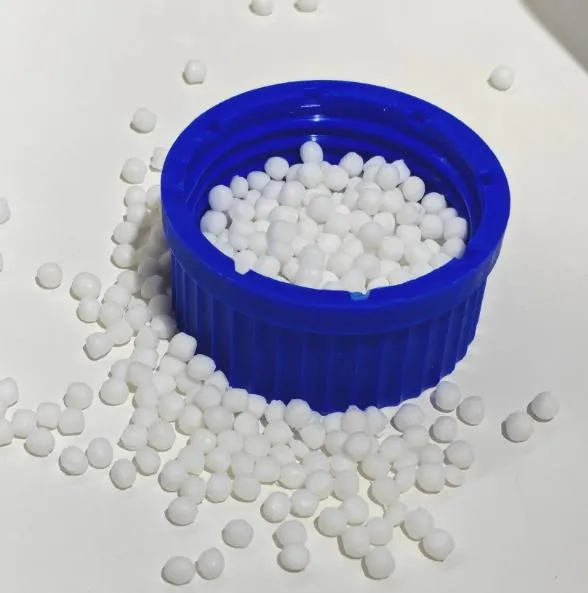

TPR Granules

Thermoplastic rubber is a material that has the elastomeric properties of rubber while being easy to process using existing thermoplastic processing equipment like injection molding. It must be noted that TPR has a different chemistry when compared to rubber and contains no latex. TPR was created to replace typical vulcanized rubber products which are more time-consuming, costly, and difficult to process.

1, TPR products can be processed on general thermoplastic molding machine, no need for special processing equipment.

2, TPR products greatly improve the production efficiency, TPR materials in the injection molding machine can be directly vulcanized

3, TPR products are easy to recycle and reduce costs. Used TPR waste can be simply regenerated and then recycled, reducing environmental pollution and expanding the source of renewable resources.

Generally, the temperature setting range of TPR products in each area is: the barrel is 160 degrees Celsius to 210 degrees Celsius, and the nozzle is 180 degrees Celsius to 230 degrees Celsius.

Widely used in automotive, construction, rail transit, home appliances, electronic appliances, footwear, medical equipment, cable, photovoltaic and other fields. At present, TPV is the most widely used in the automotive field, followed by the construction industry, and again in the field of home appliances.

A ni ọpọlọpọ awọn ile-iṣelọpọ giga-giga pẹlu ifowosowopo jinlẹ, eyiti o le fun ọ ni awọn ọja to gaju ati awọn idiyele ifigagbaga. Ati pe a tun le fun awọn ẹdinwo fun awọn rira olopobobo.Ati pe a ṣe ifọwọsowọpọ pẹlu ọpọlọpọ awọn ile-iṣẹ gbigbe ẹru ẹru ọjọgbọn, le fi awọn ọja ranṣẹ lailewu ati laisiyonu si ọwọ rẹ. Akoko ifijiṣẹ jẹ nipa awọn ọjọ 3-20 lẹhin ijẹrisi isanwo.

| Apejuwe ọja | Applications | |||

| Has good flexibility | Recyclable | |||

| Properties | Test Method | Test Condition | Unit | Typical Values |

| Physical properties | ||||

| Specific Gravity | ASTM D792 | 23ºC | g/cm* | 0.868 |

| MI | ASTM D1238 | 160ºC/5kg | g/10min | 205.5 |

| Mechanical properties | ||||

| Tensile Strength | ASTM D412 | / | MPa | 17.05 |

| Hardness | ASTM D2240 | / | Shore A | 6~8 |

| Tear resistance | ASTM D624 | / | kgf/cm | 15.37 |

| Elongation at break | ASTM D412 | / | % | 587.32 |

| Other properties | ||||

| RoHS | / | / | / | PASS |

Thermoplastic elastomer TPR, TPE is a kind of rubber with high elasticity,high strength, high resilience, and the characteristics of injection molding. ltis environmentally friendly, non-toxic and safe, has a wide range ofhardness, has excellent colorability, and is soft to the touch. Weatherresistance, fatigue resistance and temperature resistance, excellentprocessing performance, no need for vulcanization, can be recycled toreduce costs, can be used for secondary injection molding, and can be usedwith Pp plastic raw materials, PE plastic raw materials, PC engineeringplastics, PS plastics, ABS plastic raw materials lt can be coated and bondedwith other base materials, or can be molded separately.Thermoplastic elastomers have both the processing properties ofthermoplastic plastics and the physical properties of vulcanized rubberwhich can be described as a combination of the advantages of plastics andrubber.

| Excellent softness to the touch and hard application range (0A-100A), easy dyeing |

| Excellent coloration, weather resistance, fatigue resistance and temperature resistance |

| Small proportion, superior processing performance, no need to vulcanize |

| It can be recycled to reduce product costs |

| Alternative rubber, soft PVC and part silicone rubber |

| Environmental protection, non-toxic and safe |

1. Ṣe o jẹ ile-iṣẹ tabi ile-iṣẹ iṣowo kan?

A jẹ ile-iṣẹ iṣọpọ compnay ati iṣowo, ti n pese iṣẹ iduro kan.OEM le gba.

2. Ṣe o pese awọn ayẹwo? Ṣe o jẹ ọfẹ tabi afikun?

Awọn ayẹwo ọfẹ.Ọya ẹru ọkọ ayẹwo naa nilo lati san nipasẹ ẹgbẹ rẹ.

3. Ṣe o ni awọn iwe-ẹri eyikeyi ti o ni ibatan si iṣakoso didara?

ISO 9001: 2008 iwe-ẹri lati rii daju didara.

4. Kini MO yẹ ki n pese lati gba agbasọ ọrọ kan?

Pls sọ fun wa iru ọja ti o nilo, iwọn ibere, adirẹsi ati awọn ibeere pataki.Itọkasi yoo ṣee ṣe fun itọkasi rẹ ni akoko.

5. Iru ọna sisan wo ni o fẹ? Iru awọn ofin wo ni a gba?

Awọn ofin Ifijiṣẹ ti a gba: FOB, CFR, CIF, EXW;

Ti gba Owo Isanwo:USD;

Ti gba Isanwo Isanwo: T/T,Western Union; Paypal, Iṣowo Iṣowo.

Ede Sọ: Gẹẹsi.

Awọn ẹka ọja