imeli: sale@hebeidisha.com

imeli: sale@hebeidisha.com

Telefoni: +86 13315186550

Telefoni: +86 13315186550

- Aferika

- Alapania

- Amharic

- Alapi

- Armenian

- Azerbaijani

- Basque

- Pelalusiana

- Bengali

- Bosnian

- Bulgarian

- Katalana

- Sepuano

- Saina

- Saina (Taiwan)

- Kosikana

- Croatian

- Czech

- Danish

- Siamani

- Igilisi

- Eseperano

- Estonian

- Finnish

- Falani

- Frisian

- Galician

- Georgian

- Siamani

- Greek

- Gujarati

- Haiti Kereole

- Hausa

- Havaii

- Eperu

- Leai

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- Aialani

- Italia

- Iapani

- Javanese

- Kannada

- Kasaka

- Khmer

- Rwanda

- Kolea

- Kutisa

- Kirikisi

- TB

- Latina

- Latvian

- Lituaniana

- Lusemipoukisi

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maoli

- Marathi

- Mokoliana

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pasato

- Persian

- Polish

- Portuguese

- Punitapi

- Lomani

- Lusia

- Samoa

- Sikotilani Gaelic

- Serbian

- Igilisi

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sipaniolo

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Fa'a Thai

- Turkish

- tamaloloa Take

- Ukaraina

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Uelese

- Fesoasoani

- Yiddish

- Yoruba

- Zulu

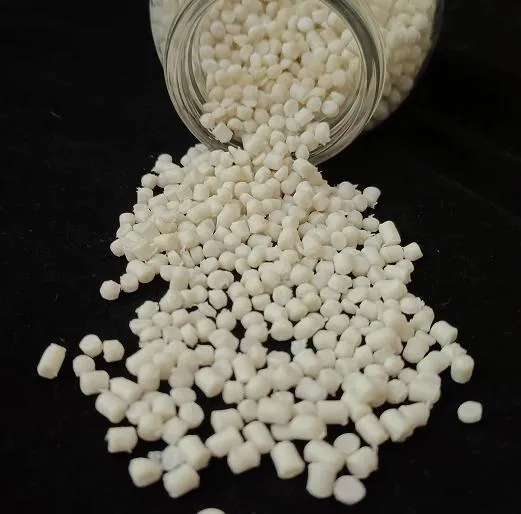

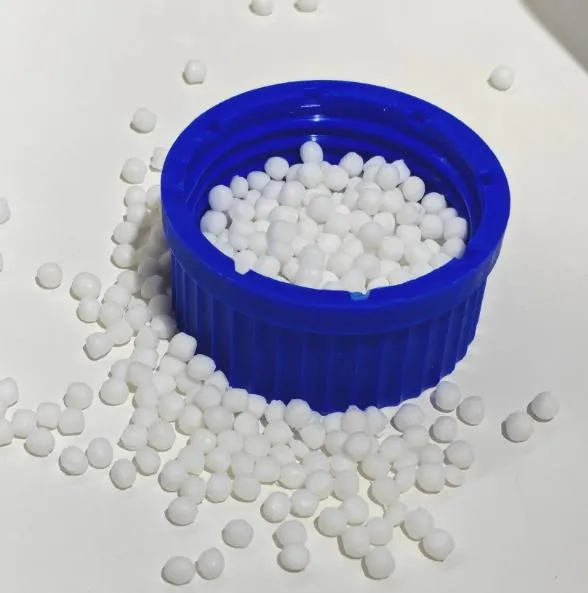

TPR Granules

Thermoplastic rubber is a material that has the elastomeric properties of rubber while being easy to process using existing thermoplastic processing equipment like injection molding. It must be noted that TPR has a different chemistry when compared to rubber and contains no latex. TPR was created to replace typical vulcanized rubber products which are more time-consuming, costly, and difficult to process.

1, TPR products can be processed on general thermoplastic molding machine, no need for special processing equipment.

2, TPR products greatly improve the production efficiency, TPR materials in the injection molding machine can be directly vulcanized

3, TPR products are easy to recycle and reduce costs. Used TPR waste can be simply regenerated and then recycled, reducing environmental pollution and expanding the source of renewable resources.

Generally, the temperature setting range of TPR products in each area is: the barrel is 160 degrees Celsius to 210 degrees Celsius, and the nozzle is 180 degrees Celsius to 230 degrees Celsius.

Widely used in automotive, construction, rail transit, home appliances, electronic appliances, footwear, medical equipment, cable, photovoltaic and other fields. At present, TPV is the most widely used in the automotive field, followed by the construction industry, and again in the field of home appliances.

E tele a matou fale gaosi oloa maualuga ma le galulue faʻatasi, lea e mafai ona tuʻuina atu ia te oe oloa maualuga ma tau faʻatauvaʻa. Ma e mafai foi ona matou tuʻuina atu faʻaitiitiga mo faʻatauga tele.Ma matou te galulue faʻatasi ma le tele o kamupani faʻapolofesa felauaiga uta, e mafai ona tuʻuina atu oloa ma le saogalemu ma le sologa lelei i ou lima. Le taimi tu'uina atu e tusa ma le 3-20 aso talu ona fa'amaonia le totogiina.

| Fa'amatalaga o oloa | Applications | |||

| Has good flexibility | Recyclable | |||

| Properties | Test Method | Test Condition | Unit | Typical Values |

| Physical properties | ||||

| Specific Gravity | ASTM D792 | 23ºC | g/cm* | 0.868 |

| MI | ASTM D1238 | 160ºC/5kg | g/10min | 205.5 |

| Mechanical properties | ||||

| Tensile Strength | ASTM D412 | / | MPa | 17.05 |

| Hardness | ASTM D2240 | / | Shore A | 6~8 |

| Tear resistance | ASTM D624 | / | kgf/cm | 15.37 |

| Elongation at break | ASTM D412 | / | % | 587.32 |

| Other properties | ||||

| RoHS | / | / | / | PASS |

Thermoplastic elastomer TPR, TPE is a kind of rubber with high elasticity,high strength, high resilience, and the characteristics of injection molding. ltis environmentally friendly, non-toxic and safe, has a wide range ofhardness, has excellent colorability, and is soft to the touch. Weatherresistance, fatigue resistance and temperature resistance, excellentprocessing performance, no need for vulcanization, can be recycled toreduce costs, can be used for secondary injection molding, and can be usedwith Pp plastic raw materials, PE plastic raw materials, PC engineeringplastics, PS plastics, ABS plastic raw materials lt can be coated and bondedwith other base materials, or can be molded separately.Thermoplastic elastomers have both the processing properties ofthermoplastic plastics and the physical properties of vulcanized rubberwhich can be described as a combination of the advantages of plastics andrubber.

| Excellent softness to the touch and hard application range (0A-100A), easy dyeing |

| Excellent coloration, weather resistance, fatigue resistance and temperature resistance |

| Small proportion, superior processing performance, no need to vulcanize |

| It can be recycled to reduce product costs |

| Alternative rubber, soft PVC and part silicone rubber |

| Environmental protection, non-toxic and safe |

1. O oe o se falegaosimea po'o se kamupani fefa'ataua'iga?

O matou o se compnay tu'ufa'atasiga alamanuia ma fefa'ataua'iga, tu'uina atu le tasi-taofi service.OEM e mafai ona talia.

2. E te tuʻuina atu faʻataʻitaʻiga? E leai se totogi pe fa'aopoopo?

Fa'ata'ita'iga fua.E mana'omia ona totogi le tau o uta a le fa'ata'ita'iga i lou itu.

3. E i ai ni au tusi faamaonia e fesoʻotaʻi ma le pulea lelei?

ISO 9001: 2008 faʻamaonia e faʻamautinoa le lelei.

4. O le a le mea e tatau ona ou saunia e maua ai se upusii?

Pls taʻu mai ia i matou le ituaiga oloa e te manaʻomia, faʻatonuga tele, tuatusi ma manaoga faʻapitoa.O le upusii o le a faia mo lau faʻamatalaga i le taimi.

5. O le a le ituaiga auala totogi e te manaʻo ai? O a ituaiga tuutuuga e talia?

Taliaina Tu'uina atu: FOB,CFR,CIF,EXW;

Talia Totogi Tupe:USD;

Tulaga Totogi Talia: T / T, Western Union; Paypal, Fefa'ataua'iga Fa'amautinoa.

Gagana Gagana: Igilisi.

Vaega o oloa