Lengolo-tsoibila: sale@hebeidisha.com

Lengolo-tsoibila: sale@hebeidisha.com

Mohala: +86 13315186550

Mohala: +86 13315186550

- Moafrika

- Sealbania

- Seamharic

- Searabia

- Searmenia

- Se-Azerbaijani

- Sebasque

- Sebelarusia

- Benghali

- Sebosnia

- Se-Bulgaria

- Secatalan

- Sebuano

- China

- China (Taiwan)

- Corsican

- Secroatia

- Czech

- Sedanishe

- Se-Dutch

- Senyesemane

- Esperanto

- Seestonia

- Sefinnishe

- Sefora

- Sefrisia

- Segalician

- Segeorgia

- Sejeremane

- Segerike

- Segujarati

- Secreole sa Haiti

- hausa

- siwaiian

- Seheberu

- Che

- Miao

- Se-Hungary

- Seiceland

- igbo

- Seindonesia

- irish

- Setaliana

- Sejapane

- Se-Javanese

- Kannada

- kazakh

- Khmer

- Rwanda

- Sekorea

- Sekurdish

- Sekyrgyz

- Lefuba

- Selatine

- Selatvia

- Selithuania

- Se-Luxembourgish

- Semacedonia

- Malgashi

- Semalay

- Semalayalam

- Semalta

- Semaori

- Marathi

- Mongolian

- Myanmar

- tsa Nepali

- Norwegian

- Norwegian

- Occitan

- Sepashto

- Sepersia

- Sepolishe

- Sepotoketsi

- Sepunjabi

- Seromania

- Serussia

- Sesamoa

- Segaeli sa Scotland

- Seserbia

- Senyesemane

- Seshona

- Sindhi

- Sesinhala

- Seslovak

- Seslovenia

- Somalia

- Sepanish

- Sesundanese

- Seswahili

- Seswedishe

- Setagalog

- Se-Tajik

- Setamil

- Setatare

- Setelugu

- Sethai

- Se-Turkey

- Turkmen

- Seukraine

- Seurdu

- Uighur

- Seuzbek

- Sevietnam

- Welsh

- Thusa

- Yiddish

- Yoruba

- Sezulu

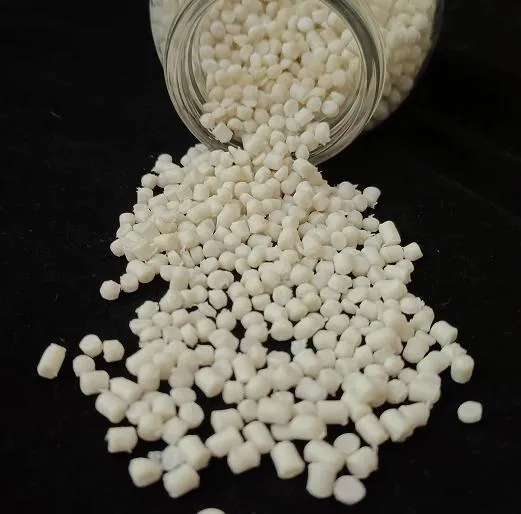

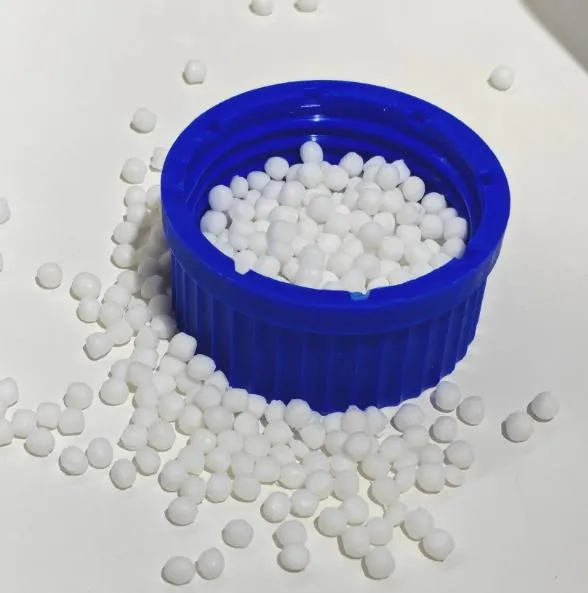

TPR Granules

Thermoplastic rubber is a material that has the elastomeric properties of rubber while being easy to process using existing thermoplastic processing equipment like injection molding. It must be noted that TPR has a different chemistry when compared to rubber and contains no latex. TPR was created to replace typical vulcanized rubber products which are more time-consuming, costly, and difficult to process.

1, TPR products can be processed on general thermoplastic molding machine, no need for special processing equipment.

2, TPR products greatly improve the production efficiency, TPR materials in the injection molding machine can be directly vulcanized

3, TPR products are easy to recycle and reduce costs. Used TPR waste can be simply regenerated and then recycled, reducing environmental pollution and expanding the source of renewable resources.

Generally, the temperature setting range of TPR products in each area is: the barrel is 160 degrees Celsius to 210 degrees Celsius, and the nozzle is 180 degrees Celsius to 230 degrees Celsius.

Widely used in automotive, construction, rail transit, home appliances, electronic appliances, footwear, medical equipment, cable, photovoltaic and other fields. At present, TPV is the most widely used in the automotive field, followed by the construction industry, and again in the field of home appliances.

Re na le lifeme tse ngata tsa boleng bo holimo tse nang le tšebelisano e tebileng, tse ka u fang lihlahisoa tsa boleng bo holimo le litheko tsa tlholisano. Hape re ka fana ka litheolelo bakeng sa ho reka ka bongata.'Me re sebelisana le lik'hamphani tse ngata tsa litsebi tse tsamaisang thepa, li ka isa lihlahisoa ka mokhoa o sireletsehileng le ka thelelo matsohong a hau. Nako ea ho fana e ka ba matsatsi a 3-20 ka mor'a hore ho netefatsoe tefo.

| Tlhaloso ea Sehlahisoa | Applications | |||

| Has good flexibility | Recyclable | |||

| Properties | Test Method | Test Condition | Unit | Typical Values |

| Physical properties | ||||

| Specific Gravity | ASTM D792 | 23ºC | g/cm* | 0.868 |

| MI | ASTM D1238 | 160ºC/5kg | g/10min | 205.5 |

| Mechanical properties | ||||

| Tensile Strength | ASTM D412 | / | MPa | 17.05 |

| Hardness | ASTM D2240 | / | Shore A | 6~8 |

| Tear resistance | ASTM D624 | / | kgf/cm | 15.37 |

| Elongation at break | ASTM D412 | / | % | 587.32 |

| Other properties | ||||

| RoHS | / | / | / | PASS |

Thermoplastic elastomer TPR, TPE is a kind of rubber with high elasticity,high strength, high resilience, and the characteristics of injection molding. ltis environmentally friendly, non-toxic and safe, has a wide range ofhardness, has excellent colorability, and is soft to the touch. Weatherresistance, fatigue resistance and temperature resistance, excellentprocessing performance, no need for vulcanization, can be recycled toreduce costs, can be used for secondary injection molding, and can be usedwith Pp plastic raw materials, PE plastic raw materials, PC engineeringplastics, PS plastics, ABS plastic raw materials lt can be coated and bondedwith other base materials, or can be molded separately.Thermoplastic elastomers have both the processing properties ofthermoplastic plastics and the physical properties of vulcanized rubberwhich can be described as a combination of the advantages of plastics andrubber.

| Excellent softness to the touch and hard application range (0A-100A), easy dyeing |

| Excellent coloration, weather resistance, fatigue resistance and temperature resistance |

| Small proportion, superior processing performance, no need to vulcanize |

| It can be recycled to reduce product costs |

| Alternative rubber, soft PVC and part silicone rubber |

| Environmental protection, non-toxic and safe |

1. Na u feme kapa k'hamphani ea khoebo?

Re komnay e kopanyang indasteri le khoebo, ho fana ka ts'ebeletso e le 'ngoe.OEM e ka amoheloa.

2. O fana ka mehlala? Na ke mahala kapa ho feta?

Mehlala ea mahala. Tefiso ea thepa ea sampole e hloka ho lefuoa ka lehlakore la hau.

3. O na le litifikeiti tse amanang le taolo ea boleng?

Setifikeiti sa ISO 9001:2008 ho netefatsa boleng.

4. Ke fane ka eng ho fumana khotheishene?

Pls re tsebise ka mofuta oa sehlahisoa seo u se hlokang, bongata ba odara, aterese le litlhoko tse ikhethileng. Khotheishene e tla etsoa bakeng sa referense ea hau ka nako.

5. U khetha mofuta ofe oa mokhoa oa ho lefa? Ke mantsoe a mofuta ofe a amoheloang?

Melao e Amoheletsoeng ea Thomello: FOB,CFR,CIF,EXW;

Chelete ea Tefo e Amoheletsoeng: USD;

Mofuta oa Tefo o Amoheletsoeng: T/T, Western Union; Paypal, Tiisetso ea Khoebo.

Puo e Builoeng: Senyesemane.

Lihlopha tsa lihlahisoa