Warning: Undefined array key "file" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

- Afrikan

- Albaniż

- Amhariku

- Għarbi

- Armenjan

- Ażerbajġani

- Bask

- Belarussu

- Bengali

- Bosnijan

- Bulgaru

- Katalan

- Cebuano

- Iċ-Ċina

- Iċ-Ċina (Tajwan)

- Korsiku

- Kroat

- Ċek

- Daniż

- Olandiż

- Ingliż

- Esperanto

- Estonjan

- Finlandiż

- Franċiż

- Friżjan

- Galizjan

- Ġorġjan

- Ġermaniż

- Grieg

- Guġarati

- Kreol Ħaitjan

- hausa

- Ħawajjan

- Ebrajk

- Le

- Miao

- Ungeriż

- Iżlandiż

- igbo

- Indoneżjan

- Irlandiż

- Taljan

- Ġappuniż

- Ġavaniż

- Kannada

- każak

- Khmer

- Rwandan

- Korean

- Kurdi

- Kirgiż

- TB

- Latin

- Latvjan

- Litwan

- Lussemburgiż

- Maċedonjan

- Malgashi

- Malajan

- Malajalam

- Malti

- Maori

- Marathi

- Mongoljan

- Il-Mjanmar

- Nepaliż

- Norveġiż

- Norveġiż

- Oċċitan

- Pashto

- Persjan

- Pollakk

- Portugiż

- Punġabi

- Rumen

- Russu

- Samoan

- Galliku Skoċċiż

- Serb

- Ingliż

- Shona

- Sindhi

- Sinħaliż

- Slovakk

- Sloven

- Somali

- Spanjol

- Sundaniż

- Swaħili

- Svediż

- Tagalog

- Taġik

- Tamil

- Tatar

- Telugu

- Tajlandiż

- Tork

- Turkmeni

- Ukrain

- Urdu

- Uighur

- Użbek

- Vjetnamiż

- Welsh

- Għajnuna

- Jiddix

- Joruba

- Żulu

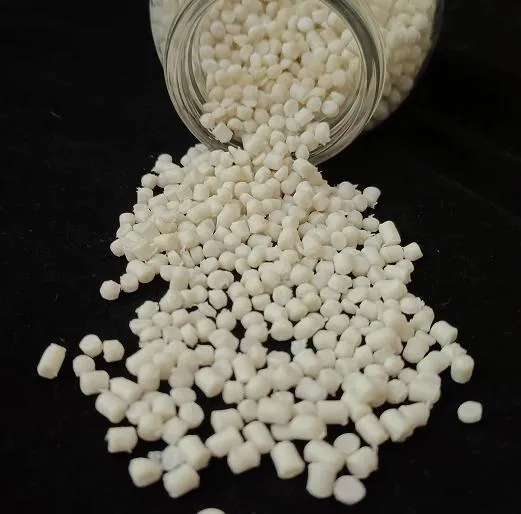

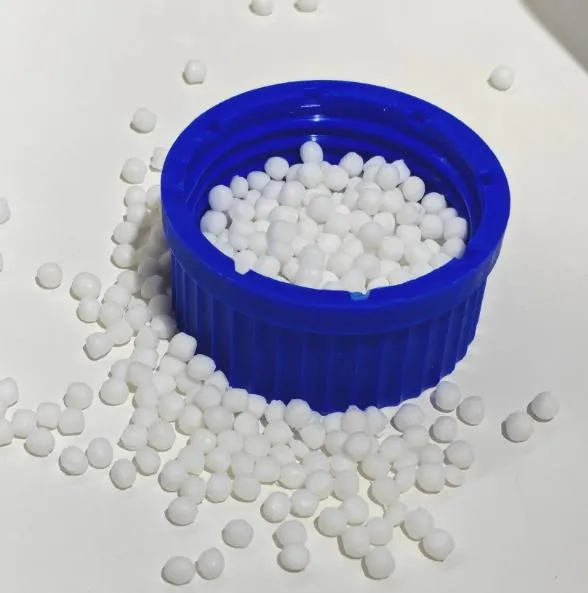

TPR Granules

Thermoplastic rubber is a material that has the elastomeric properties of rubber while being easy to process using existing thermoplastic processing equipment like injection molding. It must be noted that TPR has a different chemistry when compared to rubber and contains no latex. TPR was created to replace typical vulcanized rubber products which are more time-consuming, costly, and difficult to process.

1, TPR products can be processed on general thermoplastic molding machine, no need for special processing equipment.

2, TPR products greatly improve the production efficiency, TPR materials in the injection molding machine can be directly vulcanized

3, TPR products are easy to recycle and reduce costs. Used TPR waste can be simply regenerated and then recycled, reducing environmental pollution and expanding the source of renewable resources.

Generally, the temperature setting range of TPR products in each area is: the barrel is 160 degrees Celsius to 210 degrees Celsius, and the nozzle is 180 degrees Celsius to 230 degrees Celsius.

Widely used in automotive, construction, rail transit, home appliances, electronic appliances, footwear, medical equipment, cable, photovoltaic and other fields. At present, TPV is the most widely used in the automotive field, followed by the construction industry, and again in the field of home appliances.

Għandna ħafna fabbriki ta 'kwalità għolja b'kooperazzjoni profonda, li jistgħu jagħtuk prodotti ta' kwalità għolja u prezzijiet kompetittivi. U nistgħu wkoll nagħtu skontijiet għal xiri bl-ingrossa. U aħna nikkooperaw ma 'ħafna kumpaniji professjonali tal-ġarr tal-merkanzija, nistgħu nwasslu prodotti b'mod sikur u bla xkiel f'idejk. Il-ħin tal-kunsinna huwa ta 'madwar 3-20 jum wara l-konferma tal-ħlas.

| Deskrizzjoni tal-prodott | Applications | |||

| Has good flexibility | Recyclable | |||

| Properties | Test Method | Test Condition | Unit | Typical Values |

| Physical properties | ||||

| Specific Gravity | ASTM D792 | 23ºC | g/cm* | 0.868 |

| MI | ASTM D1238 | 160ºC/5kg | g/10min | 205.5 |

| Mechanical properties | ||||

| Tensile Strength | ASTM D412 | / | MPa | 17.05 |

| Hardness | ASTM D2240 | / | Shore A | 6~8 |

| Tear resistance | ASTM D624 | / | kgf/cm | 15.37 |

| Elongation at break | ASTM D412 | / | % | 587.32 |

| Other properties | ||||

| RoHS | / | / | / | PASS |

Thermoplastic elastomer TPR, TPE is a kind of rubber with high elasticity,high strength, high resilience, and the characteristics of injection molding. ltis environmentally friendly, non-toxic and safe, has a wide range ofhardness, has excellent colorability, and is soft to the touch. Weatherresistance, fatigue resistance and temperature resistance, excellentprocessing performance, no need for vulcanization, can be recycled toreduce costs, can be used for secondary injection molding, and can be usedwith Pp plastic raw materials, PE plastic raw materials, PC engineeringplastics, PS plastics, ABS plastic raw materials lt can be coated and bondedwith other base materials, or can be molded separately.Thermoplastic elastomers have both the processing properties ofthermoplastic plastics and the physical properties of vulcanized rubberwhich can be described as a combination of the advantages of plastics andrubber.

| Excellent softness to the touch and hard application range (0A-100A), easy dyeing |

| Excellent coloration, weather resistance, fatigue resistance and temperature resistance |

| Small proportion, superior processing performance, no need to vulcanize |

| It can be recycled to reduce product costs |

| Alternative rubber, soft PVC and part silicone rubber |

| Environmental protection, non-toxic and safe |

1. Inti fabbrika jew kumpanija kummerċjali?

Aħna kumpanija li tintegra l-industrija u l-kummerċ, li nipprovdu servizz one-stop. OEM jista 'jiġi aċċettat.

2. Inti tipprovdi kampjuni? Huwa b'xejn jew żejjed?

Kampjuni b'xejn. It-tariffa tal-merkanzija tal-kampjun trid titħallas min-naħa tiegħek.

3. Għandek xi ċertifikati relatati mal-kontroll tal-kwalità?

Ċertifikazzjoni ISO 9001:2008 biex tiġi żgurata l-kwalità.

4. X'għandi nipprovdi biex tikseb kwotazzjoni?

PLS għarrafna bit-tip ta 'prodott li għandek bżonn, kwantità tal-ordni, indirizz u rekwiżiti speċifiċi. Il-kwotazzjoni ssir għar-referenza tiegħek fil-ħin.

5. X'tip ta 'metodu ta' ħlas tippreferi? X'tip ta' termini huma aċċettati?

Termini ta ' Kunsinna Aċċettati: FOB, CFR, CIF, EXW;

Munita ta 'Ħlas Aċċettata: USD;

Tip ta' Ħlas Aċċettat: T/T,Western Union; Paypal, Assigurazzjoni tal-Kummerċ.

Lingwa Mitkellma: Ingliż.

Kategoriji ta' prodotti

-

Apr . 27, 2025Zibo will host the 2025 International Chemical ExpoZibo, a city known for its thriving chemical industry, will host the 2025 Zibo International Chemical Expo from May 16 to May 18, 2025. This highly anticipated event aims to bring together industry leaders, innovators and stakeholders from around the world to explore the latest advancements and trends in the chemical industry.

Apr . 27, 2025Zibo will host the 2025 International Chemical ExpoZibo, a city known for its thriving chemical industry, will host the 2025 Zibo International Chemical Expo from May 16 to May 18, 2025. This highly anticipated event aims to bring together industry leaders, innovators and stakeholders from around the world to explore the latest advancements and trends in the chemical industry. -

Apr . 22, 20252025 Yokohama Cosmetics Raw Materials and Technology ExhibitionYOKOHAMA, Japan – The City of Yokohama is preparing to host the much-anticipated Cosmetics Ingredients & Technologies 2025 from May 14 to May 16, 2025. The premier event is expected to attract industry professionals, innovators and enthusiasts from around the world to showcase the latest advancements in cosmetic ingredients and technologies.

Apr . 22, 20252025 Yokohama Cosmetics Raw Materials and Technology ExhibitionYOKOHAMA, Japan – The City of Yokohama is preparing to host the much-anticipated Cosmetics Ingredients & Technologies 2025 from May 14 to May 16, 2025. The premier event is expected to attract industry professionals, innovators and enthusiasts from around the world to showcase the latest advancements in cosmetic ingredients and technologies. -

Apr . 18, 20252025 India Mumbai Fine Chemicals ExhibitionMUMBAI, India – The bustling metropolis of Mumbai is gearing up to host the much-anticipated Fine Chemicals Expo on April 29-30, 2025. The premier event is expected to attract industry leaders, innovators and stakeholders from across the world to showcase the latest advancements in the fine chemicals sector.

Apr . 18, 20252025 India Mumbai Fine Chemicals ExhibitionMUMBAI, India – The bustling metropolis of Mumbai is gearing up to host the much-anticipated Fine Chemicals Expo on April 29-30, 2025. The premier event is expected to attract industry leaders, innovators and stakeholders from across the world to showcase the latest advancements in the fine chemicals sector.