Warning: Undefined array key "file" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

- Neeg African

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Tuam Tshoj

- Tuam Tshoj (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Lus Askiv

- Esperanto

- Estonian

- Finnish

- Fabkis

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- haus

- hawaiian

- Hebrew

- Tsis yog

- Miao

- Hungarian

- Icelandic

- ib igbo

- Indonesian

- irish

- Italian

- Nyiv

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandan

- Kauslim

- Kurdish

- Kyrgyz

- TB

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Lavxias

- Samoan

- Scottish Gaelic

- Serbian

- Lus Askiv

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thaib

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Nyab Laj

- Welsh

- Pab

- Yiddish

- Yoruba

- Zulu

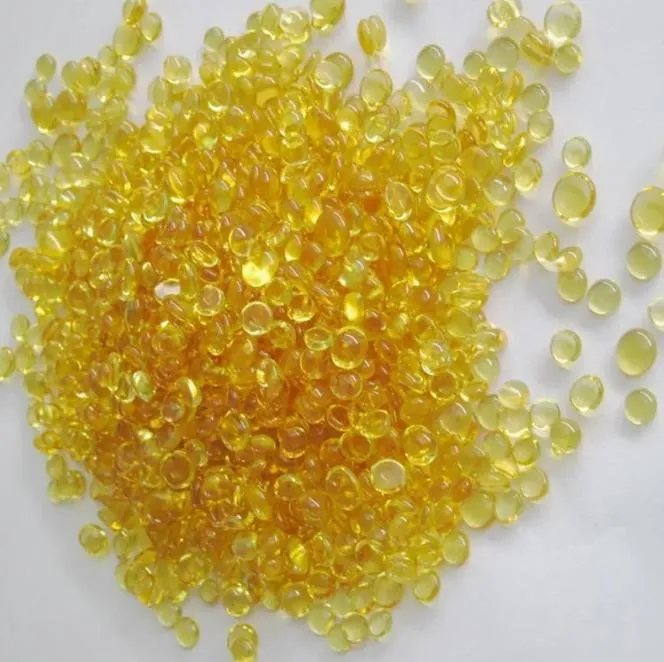

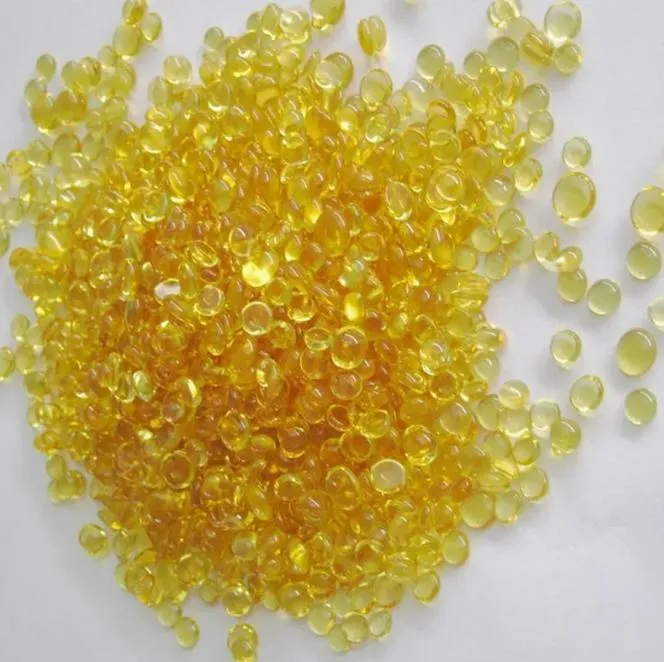

Polyamide Resin

Polyamide resin is reacted from dimer acid and diamine. This product is mainly used in gravure plastic printing inks and paper printing inks. It has very good adhesion on polyethylene material, especially be fit for printing on polyethylene film, plastic film such as tinsel composite laminated film. The printing ink which is made from this polyamide resin has good adhesion, high gloss, low freezing point, good solvent release and good compatible with nitrocotton.

Widely used in ink, hot melt adhesive.

Polyamide resin, is a wide range of chemical raw materials with excellent performance, according to its properties can be divided into two categories: non-reactive or neutral polyamide and reactive polyamide. Neutral polyamides are mainly used in the production of inks, thermal binding binders and coatings, reactive polyamides are used in epoxy resin curing agents, and thermosetting surface coatings, binders, lining materials and can sealing, mold casting resins. The neutral dimeric acid polyamide resin has good adhesion on polyethylene and other substrates, and is especially suitable for printing on plastic films such as polyethylene packaging film and metal foil composite laminate film. The ink prepared by neutral polyamide resin has luster, good bonding property, excellent alcohol dilution, low gelling property, quick drying and small odor. Dimeric acid based thermal binding resin, widely used in shoes, cans, packaging and book binding; Used for side seam sealing of can packaging; Bonding of new structural containers for frozen apples, oranges and other juices. Thermal bonding polyamide binder, because it is resistant to dry cleaning, strong detergent, bleach and high temperature washing conditions in laundry room and home, it is convenient to use and used for strong material bonding. It is used for heat shrinkable cable sleeve because of its necessary adhesion and excellent moisture resistance. Other uses of neutral polyamine resins include the preparation of thixotropic coatings, domestic water-based adhesives, fabric antistatic agents, transparent candles and detergents. The reactive polyamide resin further reacts and is used as a curing agent for epoxy resins, resulting in widespread cross-linking into thermosetting resins. When used as curing agent, it has the advantages of large randomness, non-toxicity, ability to cure at room temperature, softness and non-brittleness, which can make epoxy resin have excellent adhesion, flexural property, toughness, chemical resistance, moisture resistance and surface smoothness. Dimeric acid amine resin - the largest use of epoxy resin is binder, surface coating and can sealing, mold casting resin. The binder has good wettability, high bond strength and good internal plasticity, and can withstand greater impact force than the amine cured epoxy resin. The binder can be used as a side seam binder for metals, as well as a welding agent and caulking material for plastics and automobile bodies, and can also be used as a structural binder for metal-metal bonding. Epoxy resin cured by dimeric acid polyamide has excellent properties such as flexibility, chemical resistance, salt corrosion resistance, impact resistance and high gloss, and is widely used as surface coatings.

Peb muaj ntau lub Hoobkas zoo nrog kev koom tes sib sib zog nqus, uas tuaj yeem muab koj cov khoom zoo thiab cov nqi sib tw. Thiab peb tseem tuaj yeem muab cov luv nqi rau kev yuav khoom ntau.Thiab peb koom tes nrog ntau lub tuam txhab xa khoom xa tuaj, tuaj yeem xa cov khoom lag luam kom nyab xeeb thiab ntseeg nkaws rau koj txhais tes. Lub sij hawm xa tuaj yog li 3-20 hnub tom qab tau txais kev pom zoo ntawm kev them nyiaj.

| Type NO. | Acid value (mgKOH/g) |

Amine value (mgKOH/g |

Viscosity (mpa.s/25ºC) |

Color (Fe-Co) |

Softening pointºC | Mainly features |

| YZ-960 | <5 | <4 | 120-170 | <9 | 115-125 | Standard grade Good compatibility with nitrocotton good varnish stability |

| YZ-960A | <3 | <6 | 80-150 | <9 | 102-108 | Good low temperature stability good gloss and color |

| YZ-800 | <5 | <4 | 60-100 | <9 | 100-120 | Excellent adhesion and alcohol solubility |

| YZ-900 | <5 | <4 | 100-150 | <9 | 120-180 | Good resistance to high Temperature |

1. Koj puas yog lub Hoobkas lossis tuam txhab lag luam?

Peb yog ib qho kev sib koom ua ke kev lag luam thiab kev lag luam, muab kev pabcuam ib-nres.OEM tuaj yeem txais.

2. Koj puas muab cov qauv? Puas yog dawb lossis ntxiv?

Cov qauv dawb.Cov qauv tus nqi thauj khoom yuav tsum tau them los ntawm koj sab.

3. Koj puas muaj daim ntawv pov thawj ntsig txog kev tswj xyuas zoo?

ISO 9001: 2008 ntawv pov thawj los xyuas kom meej qhov zoo.

4. Kuv yuav muab dab tsi kom tau txais cov lus hais?

Pls qhia peb txog cov khoom lag luam uas koj xav tau, xaj kom muaj nuj nqis, chaw nyob thiab cov kev xav tau tshwj xeeb.Cov lus hais yuav ua rau koj siv sijhawm.

5. Hom kev them nqi twg koj nyiam? Cov nqe lus twg raug lees txais?

Txais Cov Lus Cog Tseg: FOB, CFR, CIF, EXW;

Txais Nyiaj Them Nqi: USD;

Accepted Payment Type: T/T,Western Union; Paypal,BTC

Lus Hais: Lus Askiv.

Cov khoom qeb

-

Apr . 27, 2025Zibo will host the 2025 International Chemical ExpoZibo, a city known for its thriving chemical industry, will host the 2025 Zibo International Chemical Expo from May 16 to May 18, 2025. This highly anticipated event aims to bring together industry leaders, innovators and stakeholders from around the world to explore the latest advancements and trends in the chemical industry.

Apr . 27, 2025Zibo will host the 2025 International Chemical ExpoZibo, a city known for its thriving chemical industry, will host the 2025 Zibo International Chemical Expo from May 16 to May 18, 2025. This highly anticipated event aims to bring together industry leaders, innovators and stakeholders from around the world to explore the latest advancements and trends in the chemical industry. -

Apr . 22, 20252025 Yokohama Cosmetics Raw Materials and Technology ExhibitionYOKOHAMA, Japan – The City of Yokohama is preparing to host the much-anticipated Cosmetics Ingredients & Technologies 2025 from May 14 to May 16, 2025. The premier event is expected to attract industry professionals, innovators and enthusiasts from around the world to showcase the latest advancements in cosmetic ingredients and technologies.

Apr . 22, 20252025 Yokohama Cosmetics Raw Materials and Technology ExhibitionYOKOHAMA, Japan – The City of Yokohama is preparing to host the much-anticipated Cosmetics Ingredients & Technologies 2025 from May 14 to May 16, 2025. The premier event is expected to attract industry professionals, innovators and enthusiasts from around the world to showcase the latest advancements in cosmetic ingredients and technologies. -

Apr . 18, 20252025 India Mumbai Fine Chemicals ExhibitionMUMBAI, India – The bustling metropolis of Mumbai is gearing up to host the much-anticipated Fine Chemicals Expo on April 29-30, 2025. The premier event is expected to attract industry leaders, innovators and stakeholders from across the world to showcase the latest advancements in the fine chemicals sector.

Apr . 18, 20252025 India Mumbai Fine Chemicals ExhibitionMUMBAI, India – The bustling metropolis of Mumbai is gearing up to host the much-anticipated Fine Chemicals Expo on April 29-30, 2025. The premier event is expected to attract industry leaders, innovators and stakeholders from across the world to showcase the latest advancements in the fine chemicals sector.

Polyamide Resin

Yellowish transparent granular solid. It is reacted from dimer acid and diamine. It has good chemical stability, good adhesion, water-fast and good folding endurance. It has very good adhesion on polyethylene material, especially be fit for printing on polyethylene film, plastic film such as tinsel composite laminated film.

It is mainly used to produce gravure plastic printing ink, paper printing ink and hot-melt adhesive. The printing ink which is made from this Polyamide resin has good adhesion, high gloss, low freezing point, good solvent release and good compatible with nitrocotton.

Peb muaj ntau lub Hoobkas zoo nrog kev koom tes sib sib zog nqus, uas tuaj yeem muab koj cov khoom zoo thiab cov nqi sib tw. Thiab peb tseem tuaj yeem muab cov luv nqi rau kev yuav khoom ntau.Thiab peb koom tes nrog ntau lub tuam txhab xa khoom xa tuaj, tuaj yeem xa cov khoom lag luam kom nyab xeeb thiab ntseeg nkaws rau koj txhais tes. Lub sij hawm xa tuaj yog li 3-20 hnub tom qab tau txais kev pom zoo ntawm kev them nyiaj.

| Yam khoom | HH-PA11 | HH-PA11C | HH-PA11H | HH-PA21 | HH-PA21C |

| Soluble | Co-soluble | Co-soluble | Co-soluble | Alcohol | Alcohol |

| Character | General grade | Frost resistance grade | High viscosity grade | General grade | Frost resistance grade |

| Acid value (mgKOH/g) | <5 | <5 | <5 | <5 | <5 |

| Amine value (mgKOH/g) | <4 | <4 | <4 | <4 | <5 |

| Viscosity (mpa.s/25ºC) | 90-160 | 90-160 | 140-180 | 90-160 | 80-160 |

| Softening point (ºC) | 110±10 | 110±10 | 110±10 | 120±10 | 120±10 |

| Color (Fe-Co) | <7 | <7 | <7 | <7 | <7 |

1. Koj puas yog lub Hoobkas lossis tuam txhab lag luam?

Peb yog ib qho kev sib koom ua ke kev lag luam thiab kev lag luam, muab kev pabcuam ib-nres.OEM tuaj yeem txais.

2. Koj puas muab cov qauv? Puas yog dawb lossis ntxiv?

Cov qauv dawb.Cov qauv tus nqi thauj khoom yuav tsum tau them los ntawm koj sab.

3. Koj puas muaj daim ntawv pov thawj ntsig txog kev tswj xyuas zoo?

ISO 9001: 2008 ntawv pov thawj los xyuas kom meej qhov zoo.

4. Kuv yuav muab dab tsi kom tau txais cov lus hais?

Pls qhia peb txog cov khoom lag luam uas koj xav tau, xaj kom muaj nuj nqis, chaw nyob thiab cov kev xav tau tshwj xeeb.Cov lus hais yuav ua rau koj siv sijhawm.

5. Hom kev them nqi twg koj nyiam? Cov nqe lus twg raug lees txais?

Txais Cov Lus Cog Tseg: FOB, CFR, CIF, EXW;

Txais Nyiaj Them Nqi: USD;

Hom Kev Them Nyiaj: T / T, Western Union; Paypal, Trade Assurance.

Lus Hais: Lus Askiv.

Cov khoom qeb

-

Apr . 27, 2025Zibo will host the 2025 International Chemical ExpoZibo, a city known for its thriving chemical industry, will host the 2025 Zibo International Chemical Expo from May 16 to May 18, 2025. This highly anticipated event aims to bring together industry leaders, innovators and stakeholders from around the world to explore the latest advancements and trends in the chemical industry.

Apr . 27, 2025Zibo will host the 2025 International Chemical ExpoZibo, a city known for its thriving chemical industry, will host the 2025 Zibo International Chemical Expo from May 16 to May 18, 2025. This highly anticipated event aims to bring together industry leaders, innovators and stakeholders from around the world to explore the latest advancements and trends in the chemical industry. -

Apr . 22, 20252025 Yokohama Cosmetics Raw Materials and Technology ExhibitionYOKOHAMA, Japan – The City of Yokohama is preparing to host the much-anticipated Cosmetics Ingredients & Technologies 2025 from May 14 to May 16, 2025. The premier event is expected to attract industry professionals, innovators and enthusiasts from around the world to showcase the latest advancements in cosmetic ingredients and technologies.

Apr . 22, 20252025 Yokohama Cosmetics Raw Materials and Technology ExhibitionYOKOHAMA, Japan – The City of Yokohama is preparing to host the much-anticipated Cosmetics Ingredients & Technologies 2025 from May 14 to May 16, 2025. The premier event is expected to attract industry professionals, innovators and enthusiasts from around the world to showcase the latest advancements in cosmetic ingredients and technologies. -

Apr . 18, 20252025 India Mumbai Fine Chemicals ExhibitionMUMBAI, India – The bustling metropolis of Mumbai is gearing up to host the much-anticipated Fine Chemicals Expo on April 29-30, 2025. The premier event is expected to attract industry leaders, innovators and stakeholders from across the world to showcase the latest advancements in the fine chemicals sector.

Apr . 18, 20252025 India Mumbai Fine Chemicals ExhibitionMUMBAI, India – The bustling metropolis of Mumbai is gearing up to host the much-anticipated Fine Chemicals Expo on April 29-30, 2025. The premier event is expected to attract industry leaders, innovators and stakeholders from across the world to showcase the latest advancements in the fine chemicals sector.