Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 6

Warning: Undefined array key "file" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

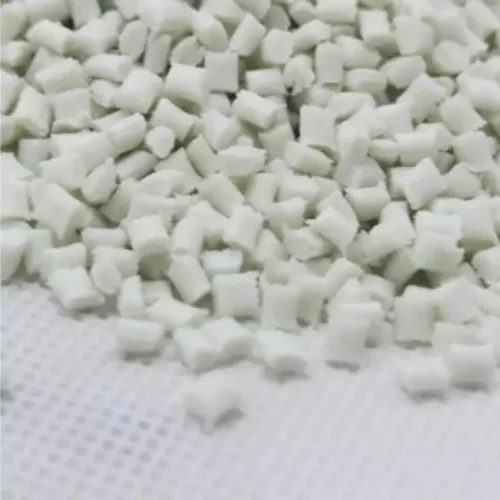

Polyethylene terephthalate PET

PET Resin is a high molecular weight polymer for general use in manufacturing containers. It can be used in the production of making packing bottles for carbonated soft drink like cola and 3-gallon, 5-gallon big bottles.

Product display

Polyethylene terephthalate (PET), chemical formula (C10H8O4) N, is by dimethyl terephthalate and ethylene glycol ester exchange or to terephthalate and ethylene glycol esterification synthesis of dihydroxyethyl terephthalate, and then the condensation reaction. Is a crystalline saturated polyester, milky white or light yellow, highly crystalline polymer, smooth and shiny surface, is a common resin in life, can be divided into APET, RPET and PETG.

- widely used in packaging, electronics, health care, construction, automotive and other fields.

2.It is used in synthetic fibers, and engineering resins often in combination with glass fiber.

3.Beverage, food and other liquid containers

We have many high-quality factories with deep cooperation, which can provide you with high quality products and competitive prices. And we can also give discounts for bulk purchases.And we cooperate with many professional freight forwarding companies, can deliver products safely and smoothly to your hands. Delivery time is about 3-20 days after confirmation of payment.

| Parameter | Unit | Limits | Test method |

| Intrinsic Viscosity | Dl/g | 0.790±0.020 | Q/WK007 |

| Acetaldehyd content | g/g | ≤1.0 | Q/WK007 |

| Color(L-value) | .. | ≥83 | Q/WK007 |

| Color(b-value) | .. | ≤-0.5 | Q/WK007 |

| Peak temperature when melting (DSC by Nitrogen) | ºC | 249±2 | Q/WK007 |

| Moisture Content | % | ≤0.2 | Q/WK007 |

PET is milky white or light yellow polymer for blowing molding, surface smooth and glossy.

PET has good creep resistance, good fatigue resistance, good corrosion resistance, high hardness.

PET electrical Insulating performanc is good.

Non-toxic, good weather resistance, chemical resistance stability, Bibulous rate is low, resistance to dilute acid and organic solvents.

Features:

1. Good electrical insulation performance, less affected by temperature, but poor corona resistance.

2. Non-toxic, weather resistance, good stability against chemicals, low water absorption, resistant to weak acids and organic solvents, but not resistant to hot water soaking, not alkali resistant.

3. The glass transition temperature of PET resin is high, the crystallization speed is slow, the molding cycle is long, the molding cycle is long, the molding shrinkage rate is large, the dimensional stability is poor, the crystallized molding is brittle, and the heat resistance is low.

4. The heat distortion temperature and long-term use temperature are very high among thermoplastic general engineering plastics.

5. Because of the high heat resistance, the reinforced PET is immersed in a solder bath at 250°C for 10 seconds, and it hardly deforms and does not change color. It is especially suitable for the preparation of electronic and electrical parts for soldering.

Application:

1. PET is mainly used for fibers, and a small amount is used for films and engineering plastics.

2. Another use of PET is blow molding products, which are used in various bottles, such as water bottles, carbonated beverage bottles, and oil bottles.

Products categories

-

Jun . 06, 2025Xanthan Gum Replacement and Powder InsightsReplacing xanthan gum, understanding xanthan gum gum properties, and selecting high-quality xanthan gum powder are critical considerations for food manufacturers and formulators.

Jun . 06, 2025Xanthan Gum Replacement and Powder InsightsReplacing xanthan gum, understanding xanthan gum gum properties, and selecting high-quality xanthan gum powder are critical considerations for food manufacturers and formulators. -

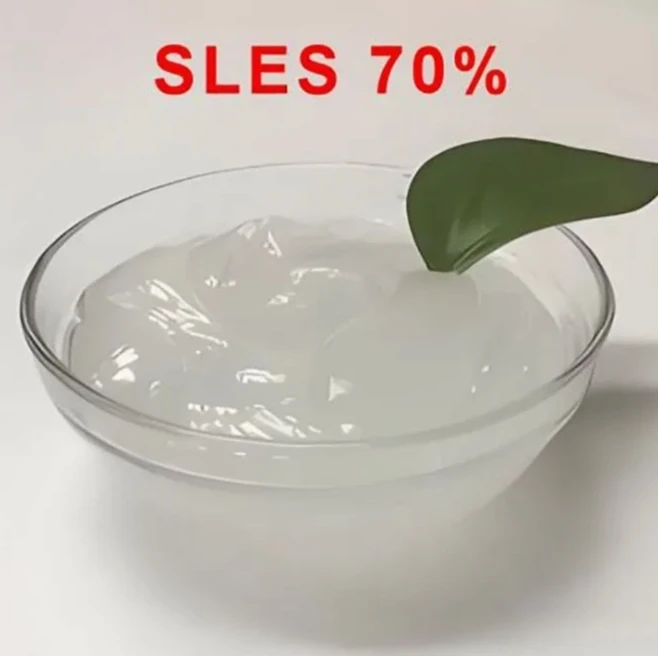

Jun . 06, 2025Exploring SLES 70 in DepthSles 70, sodium lauryl ether sulfate 70, and sodium lauryl sulfate 70 are among the most widely used surfactants in personal care and cleaning product formulations.

Jun . 06, 2025Exploring SLES 70 in DepthSles 70, sodium lauryl ether sulfate 70, and sodium lauryl sulfate 70 are among the most widely used surfactants in personal care and cleaning product formulations. -

Jun . 06, 2025E1520 Propylene Glycol Uses and Consumption PatternsE1520 propylene glycol, commonly known as propylene glycol, is a versatile chemical compound with extensive applications across multiple industries.

Jun . 06, 2025E1520 Propylene Glycol Uses and Consumption PatternsE1520 propylene glycol, commonly known as propylene glycol, is a versatile chemical compound with extensive applications across multiple industries.