Warning: Undefined array key "file" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

- អាហ្រ្វិក

- អាល់បានី

- អាំហារិក

- ភាសាអារ៉ាប់

- អាមេនី

- អាស៊ែបៃហ្សង់

- បាស

- បេឡារុស្ស

- បង់ក្លាដែស

- បូស្នៀ

- ប៊ុលហ្គារី

- កាតាឡាន

- សេប៊ូណូ

- ចិន

- ចិន (តៃវ៉ាន់)

- Corsican

- ក្រូអាត

- ឆេក

- ដាណឺម៉ាក

- ហូឡង់

- ភាសាអង់គ្លេស

- អេស្ប៉ារ៉ាន់តូ

- អេស្តូនី

- ហ្វាំងឡង់

- បារាំង

- ហ្វ្រីសៀន

- ហ្គាលីសៀន

- ហ្សកហ្ស៊ី

- អាឡឺម៉ង់

- ក្រិក

- ហ្គូចារ៉ាទី

- ក្រេអូល ហៃទី

- ហូសា

- ហាវ៉ៃ

- ភាសាហេព្រើរ

- ទេ

- មៅ

- ហុងគ្រី

- អ៊ីស្លង់

- អ៊ីកបូ

- ឥណ្ឌូនេស៊ី

- អៀរឡង់

- អ៊ីតាលី

- ជប៉ុន

- ជ្វា

- កាណាដា

- កាហ្សាក់ស្ថាន

- ខ្មែរ

- រវ៉ាន់ដា

- កូរ៉េ

- ឃឺដ

- កៀហ្ស៊ីស៊ី

- ជំងឺរបេង

- ឡាតាំង

- ឡាតវី

- លីទុយអានី

- លុចសំបួរ

- ម៉ាសេដូនៀ

- ម៉ាល់ហ្គាស៊ី

- ម៉ាឡេ

- ម៉ាឡាយ៉ាឡា

- ម៉ាល់តា

- ម៉ៅរី

- ម៉ារ៉ាធី

- ម៉ុងហ្គោលី

- មីយ៉ាន់ម៉ា

- នេប៉ាល់

- ន័រវេស

- ន័រវេស

- អូស៊ីតាន់

- ប៉ាសតូ

- ពែរ្ស

- ប៉ូឡូញ

- ព័រទុយហ្គាល់

- ពុនចាប៊ី

- រ៉ូម៉ានី

- រុស្សី

- សាម័រ

- ស្កុតឡេក

- ស៊ែប៊ី

- ភាសាអង់គ្លេស

- សូណា

- ស៊ីនឌី

- ស៊ីនហាឡា

- ស្លូវ៉ាគី

- ស្លូវេនី

- សូម៉ាលី

- ភាសាអេស្ប៉ាញ

- ស៊ុនដា

- ស្វាហ៊ីលី

- ស៊ុយអែត

- តាកាឡុក

- តាជីក

- តាមីល

- តាតា

- តេលូហ្គូ

- ថៃ

- ទួរគី

- តួកមេន

- អ៊ុយក្រែន

- អ៊ូឌូ

- អ៊ុយហ្គួរ

- អ៊ូសបេក

- វៀតណាម

- វែល

- ជំនួយ

- យីឌីស

- យូរូបា

- ហ្សូលូ

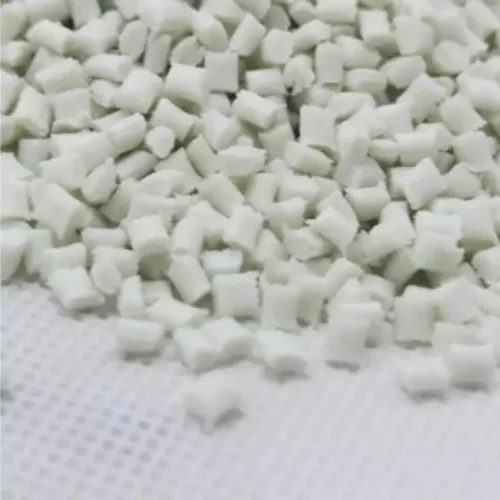

Polyethylene terephthalate PET

PET Resin is a high molecular weight polymer for general use in manufacturing containers. It can be used in the production of making packing bottles for carbonated soft drink like cola and 3-gallon, 5-gallon big bottles.

ការបង្ហាញផលិតផល

Polyethylene terephthalate (PET), chemical formula (C10H8O4) N, is by dimethyl terephthalate and ethylene glycol ester exchange or to terephthalate and ethylene glycol esterification synthesis of dihydroxyethyl terephthalate, and then the condensation reaction. Is a crystalline saturated polyester, milky white or light yellow, highly crystalline polymer, smooth and shiny surface, is a common resin in life, can be divided into APET, RPET and PETG.

- widely used in packaging, electronics, health care, construction, automotive and other fields.

2.It is used in synthetic fibers, and engineering resins often in combination with glass fiber.

3.Beverage, food and other liquid containers

យើងមានរោងចក្រដែលមានគុណភាពខ្ពស់ជាច្រើនជាមួយនឹងកិច្ចសហប្រតិបត្តិការយ៉ាងស៊ីជម្រៅ ដែលអាចផ្តល់ឱ្យអ្នកនូវផលិតផលដែលមានគុណភាពខ្ពស់ និងតម្លៃប្រកួតប្រជែង។ ហើយយើងក៏អាចផ្តល់ការបញ្ចុះតម្លៃសម្រាប់ការទិញច្រើនផងដែរ។ហើយយើងសហការជាមួយក្រុមហ៊ុនដឹកជញ្ជូនដែលមានជំនាញវិជ្ជាជីវៈជាច្រើន អាចចែកចាយផលិតផលដោយសុវត្ថិភាព និងរលូនដល់ដៃរបស់អ្នក។ ពេលវេលាដឹកជញ្ជូនគឺប្រហែល 3-20 ថ្ងៃបន្ទាប់ពីការបញ្ជាក់ការទូទាត់។

| Parameter | Unit | Limits | Test method |

| Intrinsic Viscosity | Dl/g | 0.790±0.020 | Q/WK007 |

| Acetaldehyd content | g/g | ≤1.0 | Q/WK007 |

| Color(L-value) | .. | ≥83 | Q/WK007 |

| Color(b-value) | .. | ≤-0.5 | Q/WK007 |

| Peak temperature when melting (DSC by Nitrogen) | ºC | 249±2 | Q/WK007 |

| Moisture Content | % | ≤0.2 | Q/WK007 |

PET is milky white or light yellow polymer for blowing molding, surface smooth and glossy.

PET has good creep resistance, good fatigue resistance, good corrosion resistance, high hardness.

PET electrical Insulating performanc is good.

Non-toxic, good weather resistance, chemical resistance stability, Bibulous rate is low, resistance to dilute acid and organic solvents.

Features:

1. Good electrical insulation performance, less affected by temperature, but poor corona resistance.

2. Non-toxic, weather resistance, good stability against chemicals, low water absorption, resistant to weak acids and organic solvents, but not resistant to hot water soaking, not alkali resistant.

3. The glass transition temperature of PET resin is high, the crystallization speed is slow, the molding cycle is long, the molding cycle is long, the molding shrinkage rate is large, the dimensional stability is poor, the crystallized molding is brittle, and the heat resistance is low.

4. The heat distortion temperature and long-term use temperature are very high among thermoplastic general engineering plastics.

5. Because of the high heat resistance, the reinforced PET is immersed in a solder bath at 250°C for 10 seconds, and it hardly deforms and does not change color. It is especially suitable for the preparation of electronic and electrical parts for soldering.

Application:

1. PET is mainly used for fibers, and a small amount is used for films and engineering plastics.

2. Another use of PET is blow molding products, which are used in various bottles, such as water bottles, carbonated beverage bottles, and oil bottles.

ប្រភេទផលិតផល

-

Apr . 27, 2025Zibo will host the 2025 International Chemical ExpoZibo, a city known for its thriving chemical industry, will host the 2025 Zibo International Chemical Expo from May 16 to May 18, 2025. This highly anticipated event aims to bring together industry leaders, innovators and stakeholders from around the world to explore the latest advancements and trends in the chemical industry.

Apr . 27, 2025Zibo will host the 2025 International Chemical ExpoZibo, a city known for its thriving chemical industry, will host the 2025 Zibo International Chemical Expo from May 16 to May 18, 2025. This highly anticipated event aims to bring together industry leaders, innovators and stakeholders from around the world to explore the latest advancements and trends in the chemical industry. -

Apr . 22, 20252025 Yokohama Cosmetics Raw Materials and Technology ExhibitionYOKOHAMA, Japan – The City of Yokohama is preparing to host the much-anticipated Cosmetics Ingredients & Technologies 2025 from May 14 to May 16, 2025. The premier event is expected to attract industry professionals, innovators and enthusiasts from around the world to showcase the latest advancements in cosmetic ingredients and technologies.

Apr . 22, 20252025 Yokohama Cosmetics Raw Materials and Technology ExhibitionYOKOHAMA, Japan – The City of Yokohama is preparing to host the much-anticipated Cosmetics Ingredients & Technologies 2025 from May 14 to May 16, 2025. The premier event is expected to attract industry professionals, innovators and enthusiasts from around the world to showcase the latest advancements in cosmetic ingredients and technologies. -

Apr . 18, 20252025 India Mumbai Fine Chemicals ExhibitionMUMBAI, India – The bustling metropolis of Mumbai is gearing up to host the much-anticipated Fine Chemicals Expo on April 29-30, 2025. The premier event is expected to attract industry leaders, innovators and stakeholders from across the world to showcase the latest advancements in the fine chemicals sector.

Apr . 18, 20252025 India Mumbai Fine Chemicals ExhibitionMUMBAI, India – The bustling metropolis of Mumbai is gearing up to host the much-anticipated Fine Chemicals Expo on April 29-30, 2025. The premier event is expected to attract industry leaders, innovators and stakeholders from across the world to showcase the latest advancements in the fine chemicals sector.