Imelo: sale@hebeidisha.com

Imelo: sale@hebeidisha.com

Tel: +86 13315186550

Tel: +86 13315186550

- Afirika

- Chialubaniya

- Chiamharic

- Chiarabu

- Chiameniya

- Chiazerbaijani

- Basque

- Chibelarusi

- Chibengali

- Chibosnia

- Chibugariya

- Chikatalani

- Cebuano

- China

- China (Taiwan)

- Chikosikani

- Chikroatia

- Chicheki

- Chidanishi

- Chidatchi

- Chingerezi

- Chiesperanto

- Chiestonia

- Chifinishi

- Chifalansa

- Chifrisian

- Chigalikiya

- Chijojiya

- Chijeremani

- Chigriki

- Gujarati

- Chikiliyo cha ku Haiti

- hausa

- Hawaii

- Chiheberi

- Ayi

- Miao

- Chihangare

- Chi Icelandic

- igbo

- Chi Indonesian

- ayi

- Chitaliyana

- Chijapani

- Chijavani

- Kanada

- kazakh

- Khmer

- Rwanda

- Chikorea

- Chikurdi

- Kyrgyz

- TB

- Chilatini

- Chilativiya

- Chilithuania

- ChiLuxembourgish

- Chimakedoniya

- Malgashi

- Chimalayi

- Malayalam

- Chimalta

- Chimaori

- Chimarathi

- Chimongoliya

- Myanmar

- Chinepali

- Chinorwe

- Chinorwe

- Occitan

- Pashto

- Chiperisi

- Chipolishi

- Chipwitikizi

- Chipunjabi

- Chiromania

- Chirasha

- Chisamoa

- Scottish Gaelic

- Chisebiya

- Chingerezi

- Chishona

- Sindi

- Sinhala

- Chisilovaki

- Chisiloveniya

- Somalia

- Chisipanishi

- Chisundanese

- Swahili

- Chiswidishi

- Chitagalogi

- Tajiki

- Tamil

- Chitata

- Telugu

- Thai

- Turkey

- Turkmen

- Chiyukireniya

- Chiurdu

- Uighur

- Chiuzbeki

- Vietnamese

- Welsh

- Thandizeni

- Chiyidi

- Chiyoruba

- Chizulu

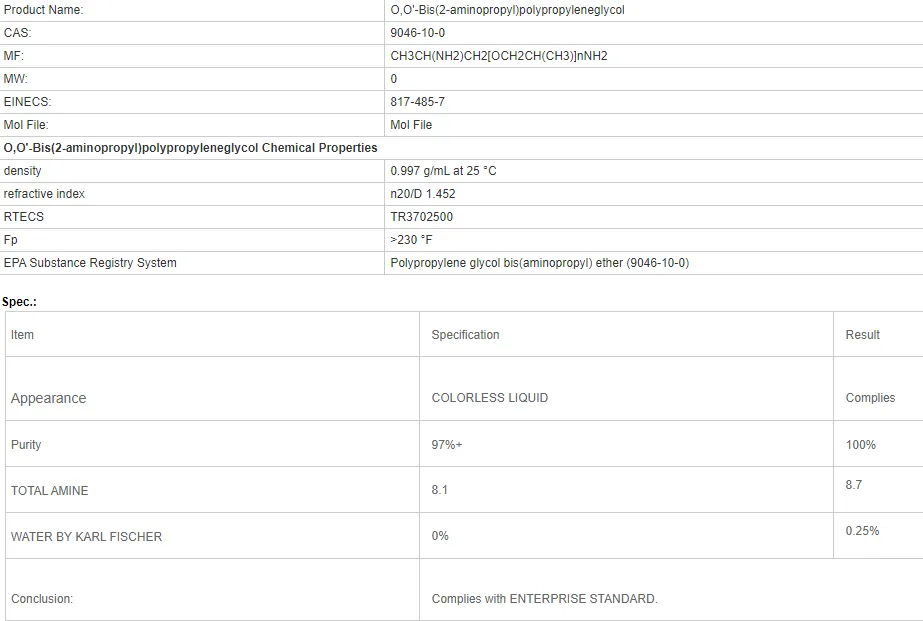

Poly(propylene glycol) bis(2-aminopropyl ether)

Poly(propylene glycol) bis(2-aminopropyl ether) is a polymer with a polyether main chain structure and an amine terminal active functional group, with the formula C3n+3H6n+10OnN2. The terminal aminopolyether has the following structure: x, y = 0-n. Poly(propylene glycol) bis(2-aminopropyl ether) is obtained by ammoniating polyethylene glycol, polypropyleneglycol, or glycol/propyleneglycol copolymer under high temperature and pressure. A series of properties such as reactivity, toughness, viscosity, and hydrophilicity of polyether amines can be adjusted by selecting different polyoxide alkyl structures, while the amine group provides the possibility for Poly(propylene glycol) bis(2-aminopropyl ether) to react with various compounds. Its special molecular structure gives Poly(propylene glycol) bis(2-aminopropyl ether) excellent comprehensive properties, commercial polyetheramines include monofunctional, bifunctional, trifunctional, molecular weight from 230 to 5000 a series of products. It has been widely used in many fields such as polyurea spraying, large composite material making, epoxy resin curing agent and automobile gasoline cleaning agent.

Terminated amino polyoxide propylene ether and terminated amino polyoxide ethylene ether, etc., the molecular structure contains ether bonds, belonging to the flexible curing agent. Specific products are divided into 3 functional T series and 2 functional D series and E series.

Soluble in ethanol, glycol ether, ketones, aliphatic hydrocarbons, aromatic hydrocarbons and other organic solvents. D-230 is soluble in water, D-400 partially soluble in water, and D-2000 is insoluble in water.

The heat release temperature of epoxy resin cured by end-group polyether decreases, and the product is colorless and transparent, with high gloss, toughness and heat shock resistance. Aminopolyether has high boiling point, low vapor pressure, little toxicity, and has potential irritation to skin.

LD50:1660mg/kg (D-230), 500 (D-400), 450 (D-2000), 230 (T-403).

Used as toughness curing agent of epoxy resin adhesive, can be used alone or mixed with ordinary polyether amine, the reference dosage is 30 ~ 60 parts, curing condition is 80℃/2h+125℃/3h.

Of course, it can also be cured at room temperature, but the bonding strength is not high, only D-400 and D-2000 are mixed at 50:25, and after curing at room temperature /7d, the peel strength is as high as 28.4kN/m, and the shear strength is 11.2mPa.

In addition, E-51: D-230= 100:30 or E-51: D-400= 100:64, with 4 parts methanol as the accelerator, the epoxy resin adhesive can be cured well at room temperature. The activity of terminal aminopolyether is low, the construction time is long, adding a small amount of accelerator nonylphenol (10 ~ 20 parts per 100 parts epoxy resin) can significantly accelerate the curing reaction speed, and improve the moisture resistance.

Amino polyether has low viscosity, colorless, good compatibility with epoxy resin, long application period and high bonding strength. Excessive use of terminated aminopolyether will reduce the bonding strength of epoxy adhesives. It can also be used as active chain extender for polyester. Also used as polyurethane and polyurea curing agent.

(1) High-performance composite materials: polyether amine can be used as a high-performance curing agent of epoxy resin for the production of high-strength and high-toughness composite materials;

(2) Polyurea: As a key component of polyurea material, there are many application examples in the waterproof system of concrete structures such as high-speed railway Bridges, cross-sea Bridges, DAMS, and large stadiums, and it has shown excellent performance;

(3) Paint: has a low viscosity, applied to epoxy floor or anticorrosive paint, can reduce the amount of solvent, reduce the viscosity of the system;

(4) Adhesive: As an epoxy resin curing agent, it has excellent toughness and fatigue resistance after full curing, and is widely used in adhesives and structural adhesives;

(5) Jewelry: has a very light color and better yellowing resistance, can be used for jewelry manufacturing.

(6) Gasoline detergent: has excellent purification, dispersion, demulsification, corrosion inhibition and antioxidant properties. It can inhibit the formation of sediment in the fuel injection nozzle, intake valve and combustion chamber. Compared with polyisobutylamine type gasoline cleaning agent, not only does it not generate sediment itself, but also can remove the original CCD (the formation of sediment in the engine combustion chamber).

Tili ndi mafakitale apamwamba kwambiri omwe ali ndi mgwirizano wozama, omwe angakupatseni mankhwala apamwamba kwambiri komanso mitengo yampikisano. Ndipo titha kuperekanso kuchotsera pogula zinthu zambiri.Ndipo timagwirizana ndi makampani ambiri otumiza katundu, amatha kubweretsa zinthu mosatekeseka m'manja mwanu. Kutumiza nthawi ndi za 3-20 masiku chitsimikiziro cha malipiro.

1. Kodi ndinu fakitale kapena kampani yamalonda?

Ndife compnay kuphatikiza makampani ndi malonda, kupereka amodzi-stop service.OEM akhoza kulandiridwa.

2. Kodi mumapereka zitsanzo? Ndi zaulere kapena zowonjezera?

Zitsanzo zaulere. Ndalama zonyamula katundu zachitsanzo ziyenera kulipidwa ndi mbali yanu.

3. Kodi muli ndi ziphaso zilizonse zokhudzana ndi kuwongolera bwino?

ISO 9001:2008 certification kuti mutsimikizire mtundu.

4. Kodi ndiyenera kupereka chiyani kuti ndilandireko mawu?

Pls amatiuza za mtundu wazinthu zomwe mukufuna, kuchuluka kwa madongosolo, ma adilesi ndi zofunikira zenizeni.

5. Mumakonda njira yolipira yanji? Ndi mawu otani omwe amavomerezedwa?

Malamulo Ovomerezeka Ovomerezeka: FOB,CFR,CIF,EXW;

Ndalama Zolipira Zovomerezeka: USD;

Mtundu wa Malipiro Ovomerezeka: T/T,Western Union; Paypal, Trade Assurance.

Chiyankhulo Cholankhulidwa:Chingerezi.

Magulu azinthu