Warning: Undefined array key "file" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

- africana

- albanès

- amàric

- àrab

- armeni

- azerbaidjana

- basc

- Bielorús

- bengalí

- bosnià

- búlgar

- català

- Cebuà

- Xina

- Xina (Taiwan)

- Cors

- croat

- txec

- danès

- holandès

- Anglès

- esperanto

- estonià

- finès

- francès

- frisó

- gallec

- georgiana

- alemany

- grec

- Gujarati

- crioll haitiano

- hausa

- hawaià

- hebreu

- No

- Miao

- hongarès

- islandès

- igbo

- indonesi

- irlandesa

- italià

- japonès

- javanès

- Kannada

- kazakh

- Khmer

- Ruandès

- coreà

- kurd

- kirguis

- TB

- llatí

- letó

- lituà

- luxemburguesa

- macedoni

- Malgashi

- Malai

- malayalam

- maltès

- Maori

- Marathi

- mongol

- Myanmar

- nepalí

- noruec

- noruec

- occità

- Pashto

- persa

- polonès

- portuguès

- panjabi

- romanès

- rus

- samoà

- Gaèlic escocès

- serbi

- Anglès

- Shona

- Sindhi

- Sinhala

- eslovac

- eslovè

- Somali

- espanyol

- Sundanès

- suahili

- suec

- Tagalog

- Tadjik

- Tamil

- Tàrtar

- Telugu

- tailandès

- turc

- turcomà

- Ucraïnès

- Urdú

- uigur

- Uzbek

- vietnamita

- gal·lès

- Ajuda

- Yiddish

- ioruba

- Zulu

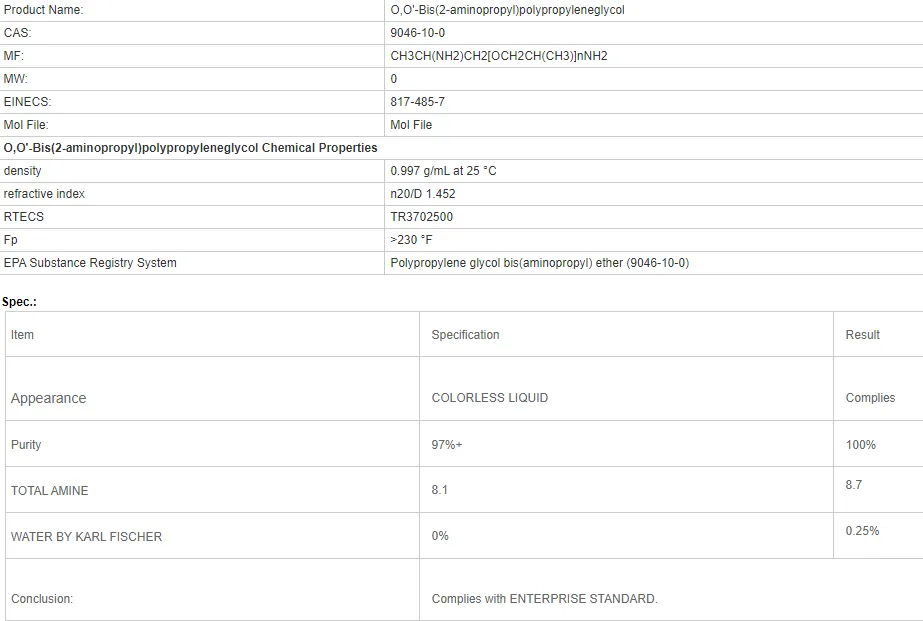

Poly(propylene glycol) bis(2-aminopropyl ether)

Poly(propylene glycol) bis(2-aminopropyl ether) is a polymer with a polyether main chain structure and an amine terminal active functional group, with the formula C3n+3H6n+10OnN2. The terminal aminopolyether has the following structure: x, y = 0-n. Poly(propylene glycol) bis(2-aminopropyl ether) is obtained by ammoniating polyethylene glycol, polypropyleneglycol, or glycol/propyleneglycol copolymer under high temperature and pressure. A series of properties such as reactivity, toughness, viscosity, and hydrophilicity of polyether amines can be adjusted by selecting different polyoxide alkyl structures, while the amine group provides the possibility for Poly(propylene glycol) bis(2-aminopropyl ether) to react with various compounds. Its special molecular structure gives Poly(propylene glycol) bis(2-aminopropyl ether) excellent comprehensive properties, commercial polyetheramines include monofunctional, bifunctional, trifunctional, molecular weight from 230 to 5000 a series of products. It has been widely used in many fields such as polyurea spraying, large composite material making, epoxy resin curing agent and automobile gasoline cleaning agent.

Terminated amino polyoxide propylene ether and terminated amino polyoxide ethylene ether, etc., the molecular structure contains ether bonds, belonging to the flexible curing agent. Specific products are divided into 3 functional T series and 2 functional D series and E series.

Soluble in ethanol, glycol ether, ketones, aliphatic hydrocarbons, aromatic hydrocarbons and other organic solvents. D-230 is soluble in water, D-400 partially soluble in water, and D-2000 is insoluble in water.

The heat release temperature of epoxy resin cured by end-group polyether decreases, and the product is colorless and transparent, with high gloss, toughness and heat shock resistance. Aminopolyether has high boiling point, low vapor pressure, little toxicity, and has potential irritation to skin.

LD50:1660mg/kg (D-230), 500 (D-400), 450 (D-2000), 230 (T-403).

Used as toughness curing agent of epoxy resin adhesive, can be used alone or mixed with ordinary polyether amine, the reference dosage is 30 ~ 60 parts, curing condition is 80℃/2h+125℃/3h.

Of course, it can also be cured at room temperature, but the bonding strength is not high, only D-400 and D-2000 are mixed at 50:25, and after curing at room temperature /7d, the peel strength is as high as 28.4kN/m, and the shear strength is 11.2mPa.

In addition, E-51: D-230= 100:30 or E-51: D-400= 100:64, with 4 parts methanol as the accelerator, the epoxy resin adhesive can be cured well at room temperature. The activity of terminal aminopolyether is low, the construction time is long, adding a small amount of accelerator nonylphenol (10 ~ 20 parts per 100 parts epoxy resin) can significantly accelerate the curing reaction speed, and improve the moisture resistance.

Amino polyether has low viscosity, colorless, good compatibility with epoxy resin, long application period and high bonding strength. Excessive use of terminated aminopolyether will reduce the bonding strength of epoxy adhesives. It can also be used as active chain extender for polyester. Also used as polyurethane and polyurea curing agent.

(1) High-performance composite materials: polyether amine can be used as a high-performance curing agent of epoxy resin for the production of high-strength and high-toughness composite materials;

(2) Polyurea: As a key component of polyurea material, there are many application examples in the waterproof system of concrete structures such as high-speed railway Bridges, cross-sea Bridges, DAMS, and large stadiums, and it has shown excellent performance;

(3) Paint: has a low viscosity, applied to epoxy floor or anticorrosive paint, can reduce the amount of solvent, reduce the viscosity of the system;

(4) Adhesive: As an epoxy resin curing agent, it has excellent toughness and fatigue resistance after full curing, and is widely used in adhesives and structural adhesives;

(5) Jewelry: has a very light color and better yellowing resistance, can be used for jewelry manufacturing.

(6) Gasoline detergent: has excellent purification, dispersion, demulsification, corrosion inhibition and antioxidant properties. It can inhibit the formation of sediment in the fuel injection nozzle, intake valve and combustion chamber. Compared with polyisobutylamine type gasoline cleaning agent, not only does it not generate sediment itself, but also can remove the original CCD (the formation of sediment in the engine combustion chamber).

Tenim moltes fàbriques d'alta qualitat amb una profunda cooperació, que us poden oferir productes d'alta qualitat i preus competitius. I també podem oferir descomptes per a compres a granel. I cooperem amb moltes empreses de transport de mercaderies professionals, podem lliurar productes de manera segura i sense problemes a les vostres mans. El termini de lliurament és d'uns 3-20 dies després de la confirmació del pagament.

1. Sou una fàbrica o una empresa comercial?

Som una empresa que integra la indústria i el comerç, que ofereix un servei únic. Es podria acceptar OEM.

2. Proporcioneu mostres? És gratuït o extra?

Mostres gratuïtes. La tarifa de transport de la mostra s'ha de pagar pel vostre costat.

3. Té algun certificat relacionat amb el control de qualitat?

Certificació ISO 9001:2008 per garantir la qualitat.

4. Què he de proporcionar per obtenir un pressupost?

Si us plau, informeu-nos del tipus de producte que necessiteu, la quantitat de la comanda, l'adreça i els requisits específics. La cotització es farà per a la vostra referència a temps.

5. Quin tipus de mètode de pagament prefereixes? Quin tipus de condicions s'accepten?

Condicions de lliurament acceptades: FOB, CFR, CIF, EXW;

Moneda de pagament acceptada: USD;

Tipus de pagament acceptat: T/T, Western Union; Paypal, assegurança comercial.

Idioma parlat: anglès.

Categories de productes

-

May . 13, 20252025 European Fine Chemicals Exhibition in GermanyThe much-anticipated Fine Chemicals Europe 2025 will be held in Germany from June 4 to 5, 2025. The event will bring together industry leaders, innovators and stakeholders in the fine chemicals sector, providing a unique platform for networking, collaboration and showcasing the latest advances in the field.

May . 13, 20252025 European Fine Chemicals Exhibition in GermanyThe much-anticipated Fine Chemicals Europe 2025 will be held in Germany from June 4 to 5, 2025. The event will bring together industry leaders, innovators and stakeholders in the fine chemicals sector, providing a unique platform for networking, collaboration and showcasing the latest advances in the field. -

May . 07, 20252025 New York Cosmetics Ingredients ExhibitionThe much-anticipated 2025 Cosmetics Ingredients New York will be held at the Javits Center in New York from June 3 to 4, 2025. This event will bring together industry leaders, innovators and enthusiasts from all over the world to discuss the latest trends and advances in the field of cosmetic ingredients.

May . 07, 20252025 New York Cosmetics Ingredients ExhibitionThe much-anticipated 2025 Cosmetics Ingredients New York will be held at the Javits Center in New York from June 3 to 4, 2025. This event will bring together industry leaders, innovators and enthusiasts from all over the world to discuss the latest trends and advances in the field of cosmetic ingredients. -

Apr . 27, 2025Zibo will host the 2025 International Chemical ExpoZibo, a city known for its thriving chemical industry, will host the 2025 Zibo International Chemical Expo from May 16 to May 18, 2025. This highly anticipated event aims to bring together industry leaders, innovators and stakeholders from around the world to explore the latest advancements and trends in the chemical industry.

Apr . 27, 2025Zibo will host the 2025 International Chemical ExpoZibo, a city known for its thriving chemical industry, will host the 2025 Zibo International Chemical Expo from May 16 to May 18, 2025. This highly anticipated event aims to bring together industry leaders, innovators and stakeholders from around the world to explore the latest advancements and trends in the chemical industry.