Warning: Undefined array key "file" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

- アフリカ人

- アルバニア語

- アムハラ語

- アラビア語

- アルメニア語

- アゼルバイジャン語

- バスク語

- ベラルーシ語

- ベンガル語

- ボスニア語

- ブルガリア語

- カタロニア語

- セブアノ語

- 中国

- 中国(台湾)

- コルシカ

- クロアチア語

- チェコ語

- デンマーク語

- オランダの

- 英語

- エスペラント

- エストニア語

- フィンランド語

- フランス語

- フリジア語

- ガリシア語

- ジョージア語

- ドイツ人

- ギリシャ語

- グジャラート語

- ハイチ語

- ハウサ語

- ハワイアン

- ヘブライ語

- いいえ

- ミャオ族

- ハンガリー語

- アイスランド語

- イボ語

- インドネシア語

- アイルランド人

- イタリアの

- 日本語

- ジャワ語

- カンナダ語

- カザフ語

- クメール語

- ルワンダ語

- 韓国語

- クルド

- キルギス語

- 結核

- ラテン

- ラトビア語

- リトアニア語

- ルクセンブルク語

- マケドニアの

- マルガシ

- マレー語

- マラヤーラム語

- マルタ語

- マオリ語

- マラーティー語

- モンゴル語

- ミャンマー

- ネパール語

- ノルウェー語

- ノルウェー語

- オック語

- パシュトゥー語

- ペルシャ語

- 研磨

- ポルトガル語

- パンジャブ語

- ルーマニア語

- ロシア

- サモア語

- スコットランド・ゲール語

- セルビア語

- 英語

- ショナ語

- シンディー語

- シンハラ語

- スロバキア語

- スロベニア語

- ソマリ語

- スペイン語

- スンダ人

- スワヒリ語

- スウェーデンの

- タガログ語

- タジク語

- タミル語

- タタール語

- テルグ語

- タイ語

- トルコ語

- トルクメン語

- ウクライナ語

- ウルドゥー語

- ウイグル

- ウズベク語

- ベトナム語

- ウェールズ語

- ヘルプ

- イディッシュ語

- ヨルバ語

- ズールー語

Hydroxy silicone oil

The COSIL F series of hydroxypolysiloxanes is a hydroxyl terminated polydimethylsiloxane. It is a series of functional polymers with different viscosities and different contents of terminal hydroxyl groups. Low-viscosity polymers can be used for filler surface treatment and anti-structuring additives for high-temperature adhesives, and can also be used in room-temperature adhesive formulations. Low-viscosity hydroxy silicone oils can also be used as reactive diluents to adjust the overall viscosity of the formulation.

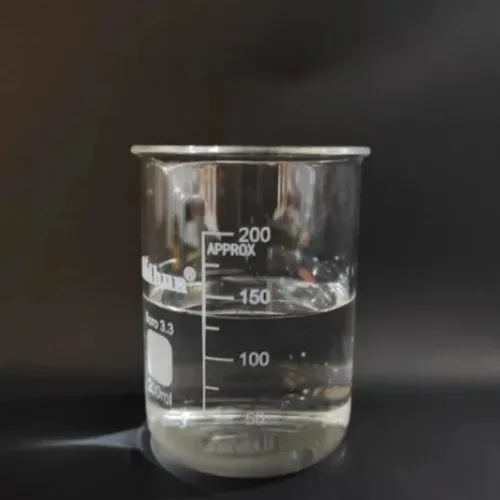

製品展示

Hydroxy silicone oil is made by polymerization of siloxane monomers, the molecular silicone materials have hydroxyl groups at both ends. The structural formula is as follows:

HO-Si (CH3) 2 O [Si (CH3) 2 O] n Si(CH3)2-OH

Chemical name is a, w- dihydroxy polydimethylsiloxane

It name 107 silicone rubber when the viscosity is above 2500mPa.S.

In addition to the general performance of methyl silicone oil, it also has reactive hydroxyl groups, it can be made available some new material or crosslinked into elastomers (or membrane) .

Colorless transparent liquid with excellent electrical insulating properties and resistance to high temperature, high flash point, low freezing point, long-term used -50 o C ~ +250 o C conditions, low the viscosity-temperature coefficient, high compression ratio, low surface tension, hydrophobic moisture resistance, chemical inertness, physiologically inertness.

It is widely used in the fields of silicone rubber industry, electronic appliances, building materials, leather material processing, plastic processing, motor manufacturing, petrochemical industry, textile printing and dyeing, medicine and health and technology.

当社は、緊密な協力関係にある多くの高品質の工場を有しており、高品質の製品と競争力のある価格を提供できます。また、大量購入には割引も提供できます。また、当社は多くの専門の貨物運送会社と協力し、製品を安全かつスムーズにお客様の手元に届けることができます。納期は、支払い確認後約3〜20日です。

|

Model |

外観 |

Density (g/cm3) |

Volatile (%) |

Viscosity (mPa.s) |

|

F-004 |

Clear transparent liquid |

0.95 |

- |

40 |

|

F-007 |

|

0.96 |

- |

70 |

|

F-075 |

|

0.97 |

<1 |

750 |

|

F-1.5 |

|

0.98 |

<1 |

1500 |

|

1F-3 |

|

0.98 |

<1 |

3000 |

|

F-6 |

|

0.98 |

<1 |

6000 |

|

F-20 |

|

0.98 |

<1 |

20000 |

|

F-50 |

|

0.98 |

<1 |

50000 |

|

F-80 |

|

0.98 |

<1 |

80000 |

|

F-300 |

|

0.98 |

<1 |

300000 |

この商品は何ですか?

Usually with the curing agent to achieve the crosslinking, it must be fixed by means of a coupling agent for the release paper, generally the curing agent is about 3 to 5% of gum base, the coupling agent is about 0.5 to 1 % of gum base.

In most cases the solvent was diluted with 10 times the first gum base, then add the coupling agent and the curing agent after mixing uniformly coated on the substrate surface at room temperature or heat curing. It need over 30 minutes at room temperature, and 30 seconds for 120 ~ 150 o C. there is no need any solvents for sealants and molds for rubber, add the curing agent and stir ( one-component and two-component curing agent is used is not the same ) , after 30 to 120 minutes degassing it can be cured .

応用

Depending on the hydroxyl content and viscosity, respectively for different industries .

- the medium-high viscosity of the product can be used as a paper -based of anti- adhesive agent, the cured film has excellent anti-sticking effect, such as the label backing paper , asphalt wrapping, sealing tape base paper, decor paper end paper processing.

- in the electrical power industry as the main component insulating paint or a component of the insulator.

- Used as a condensation-type RTV silicone rubber based adhesive and diluted material, such as sealants and plastic mold base material.

- Alter dimethyl silicone oil, and easy to emulsify .

- Small molecule hydroxyl silicone oil (25 ~ 30CP, hydroxyl content of about 8%) is an excellent control agent of silicone rubber, it not only simplifies the process of silicone rubber to improve the processing performance ( reduce heat treatment ) but also increased the transparency of products, improved working conditions .

- New development applications.

製品カテゴリー

-

May . 13, 20252025 European Fine Chemicals Exhibition in GermanyThe much-anticipated Fine Chemicals Europe 2025 will be held in Germany from June 4 to 5, 2025. The event will bring together industry leaders, innovators and stakeholders in the fine chemicals sector, providing a unique platform for networking, collaboration and showcasing the latest advances in the field.

May . 13, 20252025 European Fine Chemicals Exhibition in GermanyThe much-anticipated Fine Chemicals Europe 2025 will be held in Germany from June 4 to 5, 2025. The event will bring together industry leaders, innovators and stakeholders in the fine chemicals sector, providing a unique platform for networking, collaboration and showcasing the latest advances in the field. -

May . 07, 20252025 New York Cosmetics Ingredients ExhibitionThe much-anticipated 2025 Cosmetics Ingredients New York will be held at the Javits Center in New York from June 3 to 4, 2025. This event will bring together industry leaders, innovators and enthusiasts from all over the world to discuss the latest trends and advances in the field of cosmetic ingredients.

May . 07, 20252025 New York Cosmetics Ingredients ExhibitionThe much-anticipated 2025 Cosmetics Ingredients New York will be held at the Javits Center in New York from June 3 to 4, 2025. This event will bring together industry leaders, innovators and enthusiasts from all over the world to discuss the latest trends and advances in the field of cosmetic ingredients. -

Apr . 27, 2025Zibo will host the 2025 International Chemical ExpoZibo, a city known for its thriving chemical industry, will host the 2025 Zibo International Chemical Expo from May 16 to May 18, 2025. This highly anticipated event aims to bring together industry leaders, innovators and stakeholders from around the world to explore the latest advancements and trends in the chemical industry.

Apr . 27, 2025Zibo will host the 2025 International Chemical ExpoZibo, a city known for its thriving chemical industry, will host the 2025 Zibo International Chemical Expo from May 16 to May 18, 2025. This highly anticipated event aims to bring together industry leaders, innovators and stakeholders from around the world to explore the latest advancements and trends in the chemical industry.