Warning: Undefined array key "file" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

- Afriken

- Albanè

- Amarik

- Arab

- Amenyen

- Azerbaydjan

- Basque

- Belarisyen

- Bengali

- Bosnyen

- Bulgarian

- Catalan

- Cebuano

- Lachin

- Lachin (Taiwan)

- Kors

- Kwoasyen

- Czech

- Danwa

- Olandè

- angle

- Esperanto

- Estonyen

- Finnish

- franse

- Frisyen

- Galisyen

- Jòjyen

- Alman

- grèk

- Gujarati

- Kreyòl ayisyen

- hausa

- Hawaiian

- ebre

- Non

- Miao

- Ongwa

- Icelandic

- igbo

- Endonezyen

- Ilandè

- Italyen

- Japonè

- Javanèz

- Kannada

- kazak

- Khmer

- Rwandan

- Koreyen

- Kurdish

- Kyrgyz

- TB

- Latin

- Latvian

- Lityanyen

- Luxembourgish

- Masedwan

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolyen

- Myanma

- Nepali

- Nòvejyen

- Nòvejyen

- Occitan

- Pashto

- Pèsik

- Polonè

- Pòtigè

- Punjabi

- Woumen

- Ris

- Samoan

- Scottish Gaelic

- Sèb

- angle

- Shona

- Sindhi

- Sinhala

- Slovak

- Sloveni

- Somalyen

- Panyòl

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Tik

- Tirkmen

- Ukrainian

- Oudou

- Ouygur

- Ouzbek

- Vyetnamyen

- Welsh

- Ede

- Yiddish

- Yoruba

- Zoulou

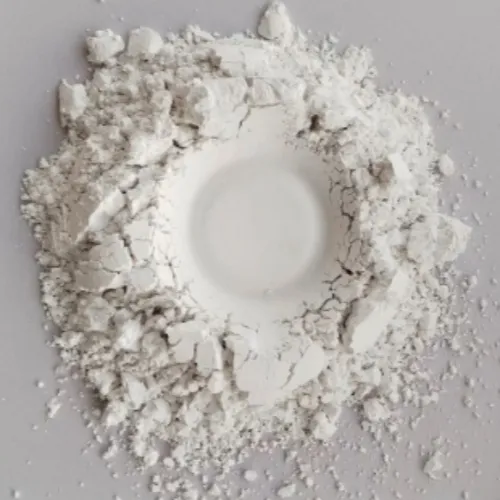

Calcium Carbonate

Heavy calcium carbonate, also called ground calcium carbonate, is produced by natural superior calcite, which has high purity and whiteness. The size ranges from under 400 mesh which is called primary products, to 2000 mesh or above, depending on your requirement.

Heavy (Ground) Calcium Carbonate is widely used as filler and improver in plastic, paint, paper-making, rubber, pharmacy, feed, daily chemical, ceramics, adhesives and ink industry.

Ekspozisyon pwodwi

- Chemical Name:Calcium carbonate

2. Molecular Formula: CaCO3

3. Molecular Weight: 100.09

4. CAS: 471-34-1

5. Shelf life: 24 months

6. Character: It is fine, white or colorless, microcrystalline powder. It is stable in air, and it is practically insoluble in water and in alcohol. The presence of any ammonium salt or carbon dioxide increases its solubility in water, but the presence of any alkali hydroxide reduces the solubility.

7. Usages: pH control agent; nutrient; dough conditioner; firming agent; yeast nutrient.

1)Rubber:

it can reduce the amount of expensive natural rubber,increase its volume ,reduce costs, After adding calcium carbonate then can be obtain higher strength tensile ,tear strength and abrasion resistance than the pure Rubber vulcanizate

2)Chemical manufacturing materials

it is heat-proof, chemical corrosion-proof,cold-proof, anti-noise, shockproof and easy to process. Therefore it can be used to make doors, dry motar ,ceilings, wallboard,waterpipe,handrail of stairs,floor board and electric wire,etc.

3)Painting& coating:

it is as the filling and as the framework, Latex paint more than 30% amount are used in thick paint ,26%-60% amount are used in water-based pain

4)Plastic:

it can increase the volume of plastics, reduce the costs, improve the size, stability, hardness and tenacity of plastic products.

5)Paperpulp material:

it can fully make use of its high whiteness, affinity to water and shock intensity, low cost widely using .

6) Coal-fired power and planted sulfurization

7)Feed,pharmaceutical industry

making calcium additives, replace the original shell powder to reduce costs.

Nou gen anpil faktori-wo kalite ak gwo koperasyon, ki ka ba ou bon jan kalite pwodwi ak pri konpetitif. Epi nou ka bay tou rabè pou acha esansyèl. Epi nou kolabore ak anpil konpayi transpò machandiz pwofesyonèl, ka delivre pwodwi san danje epi san pwoblèm nan men ou. Tan livrezon se sou 3-20 jou apre konfimasyon peman an.

|

ATIK TÈS

|

TEST STANDARD

|

TEST RESULT

|

||

|

CaCO3 %

|

≥98%

|

99%

|

||

|

Imidite

|

≤0.3%

|

0.3%

|

||

|

WHITENESS

|

≥92%

|

95.5%

|

||

|

PH

|

8-10

|

9.3

|

||

|

PB

|

≤0.001%

|

_

|

||

|

FE

|

≤0.1%

|

0.05%

|

||

|

MN

|

≤0.0045%

|

-

|

||

|

MESH

|

-

|

400 MESH

|

||

|

CONCLUSION

|

SUPERIOR PRODUCTS

|

|||

- Nano calcium carbonate features

1. Good liquidity ,easy to stirring when PVC plastify and improving processability, such as contractibility rate, surface flatness and anti-yellowing.

2.Improving surface lustrousness: good mixture with PVC and nice lustrousness. low density and good tear resistance in PVC film.

3.Excellent nano features: surface activity help resolve negatively charged electrons and Positively charged hole in ultraviolet light, excellent activity make easy chemical reaction with oxygen and organism , improving ageing resistance.

4. Mature application: big quantity fillers in PVC soft products

2.Application

1)Rubber: it can reduce the amount of expensive natural rubber,increase its volume ,reduce costs, After adding calcium carbonate then can be obtain higher strength tensile ,tear strength and abrasion resistance than the pure Rubber vulcanizate

2)Chemical manufacturing materials: it is heat-proof, chemical corrosion-proof,cold-proof, anti-noise, shockproof and easy to process. Therefore it can be used to make doors, dry motar ,ceilings, wallboard,waterpipe,handrail of stairs,floor board and electric wire,etc.

3)Painting& coating: it is as the filling and as the framework, Latex paint more than 30% amount are used in thick paint ,26%-60% amount are used in water-based pain

4)Plastic, it can increase the volume of plastics, reduce the costs, improve the size, stability, hardness and tenacity of plastic products.

5)Paperpulp material: it can fully make use of its high whiteness, affinity to water and shock intensity, low cost widely using .

Kategori pwodwi yo

-

Apr . 27, 2025Zibo will host the 2025 International Chemical ExpoZibo, a city known for its thriving chemical industry, will host the 2025 Zibo International Chemical Expo from May 16 to May 18, 2025. This highly anticipated event aims to bring together industry leaders, innovators and stakeholders from around the world to explore the latest advancements and trends in the chemical industry.

Apr . 27, 2025Zibo will host the 2025 International Chemical ExpoZibo, a city known for its thriving chemical industry, will host the 2025 Zibo International Chemical Expo from May 16 to May 18, 2025. This highly anticipated event aims to bring together industry leaders, innovators and stakeholders from around the world to explore the latest advancements and trends in the chemical industry. -

Apr . 22, 20252025 Yokohama Cosmetics Raw Materials and Technology ExhibitionYOKOHAMA, Japan – The City of Yokohama is preparing to host the much-anticipated Cosmetics Ingredients & Technologies 2025 from May 14 to May 16, 2025. The premier event is expected to attract industry professionals, innovators and enthusiasts from around the world to showcase the latest advancements in cosmetic ingredients and technologies.

Apr . 22, 20252025 Yokohama Cosmetics Raw Materials and Technology ExhibitionYOKOHAMA, Japan – The City of Yokohama is preparing to host the much-anticipated Cosmetics Ingredients & Technologies 2025 from May 14 to May 16, 2025. The premier event is expected to attract industry professionals, innovators and enthusiasts from around the world to showcase the latest advancements in cosmetic ingredients and technologies. -

Apr . 18, 20252025 India Mumbai Fine Chemicals ExhibitionMUMBAI, India – The bustling metropolis of Mumbai is gearing up to host the much-anticipated Fine Chemicals Expo on April 29-30, 2025. The premier event is expected to attract industry leaders, innovators and stakeholders from across the world to showcase the latest advancements in the fine chemicals sector.

Apr . 18, 20252025 India Mumbai Fine Chemicals ExhibitionMUMBAI, India – The bustling metropolis of Mumbai is gearing up to host the much-anticipated Fine Chemicals Expo on April 29-30, 2025. The premier event is expected to attract industry leaders, innovators and stakeholders from across the world to showcase the latest advancements in the fine chemicals sector.