Warning: Undefined array key "file" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

- Aprikano

- Albaniano

- Amharic

- Arabiko

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatiano

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- Pransiya

- Frisian

- Galician

- Georgian

- Aleman

- Griyego

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebreohanon

- dili

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italyano

- Hapon

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandan

- Koreano

- Kurdish

- Kyrgyz

- TB

- Latin

- Latviano

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persianhon

- kahamis

- Portuges

- Punjabi

- Romaniano

- Ruso

- Samoano

- Scottish Gaelic

- Serbiano

- English

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Kinatsila

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turko

- Turkmen

- Ukrainiano

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Tabang

- Yiddish

- Yoruba

- Zulu

Silicon Carbide

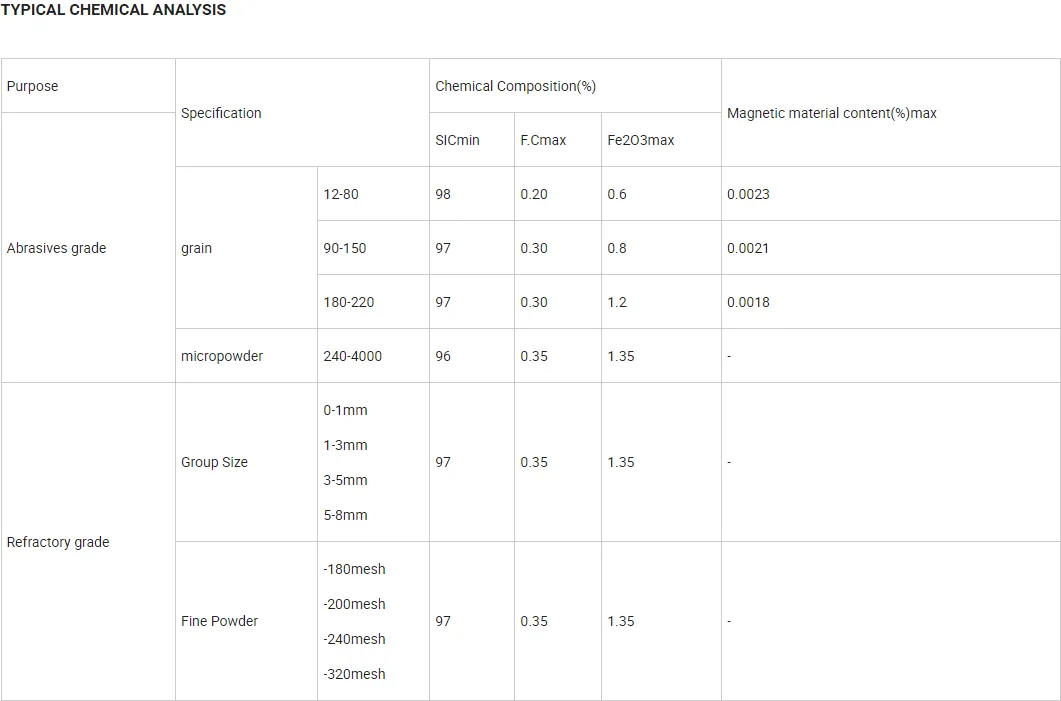

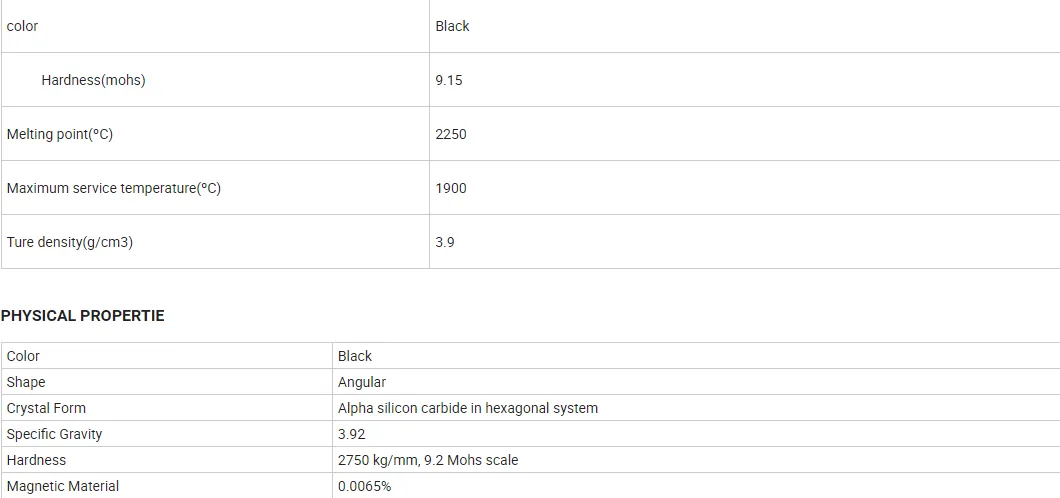

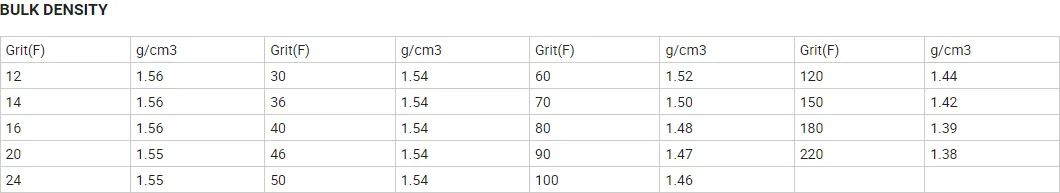

Silicon carbide, an inorganic compound with the chemical formula SiC, is produced by high-temperature smelting of quartz sand, petroleum coke (or coal coke), and wood chips (salt is added when producing green silicon carbide) in a resistance furnace. Silicon carbide is a semiconductor and exists in the form of the extremely rare mineral moissanite in nature. It has been mass-produced as powder and crystals since 1893 and is used as an abrasive, among other things. Of the non-oxide high-tech refractory raw materials such as C, N, and B, silicon carbide is the most widely used and economical, and can be called garnet sand or refractory sand. In China, industrial-produced silicon carbide is divided into black silicon carbide and green silicon carbide, both of which are hexagonal crystals.

Silicon carbide has two commonly used varieties of black silicon carbide and green silicon carbide, both of which belong to alpha-SiC.

① Black silicon carbide contains about 95% SiC, which has higher toughness than green silicon carbide, and is mostly used to process materials with low tensile strength, such as glass, ceramics, stone materials, refractory materials, cast iron, and non-ferrous metals.

② Green silicon carbide contains more than 97% SiC, has good self-sharpening properties, and is mostly used to process cemented carbide, titanium alloys, and optical glass. It is also used for honing cylinder liners and fine grinding high-speed steel tools. In addition, there is also cubic silicon carbide, which is a yellow-green crystal obtained by special process, and the grinding tools made of it are suitable for ultra-precision processing of bearings, which can process the surface roughness from Ra32 to 0.16 microns to Ra0.04 to 0.02 microns in one process.

Due to its high thermal stability, high strength, high thermal conductivity, etc., it is widely used in atomic energy materials, chemical devices, high-temperature treatment, electric heating elements, and resistors, etc. It is used in abrasives, wear-resistant agents, abrasives, high-grade refractory materials, and fine ceramics.

It is used in abrasives, wear-resistant agents, abrasives, high-grade refractory materials, and fine ceramics.

It is suitable for manufacturing various types of silicon carbide abrasives and ceramic kiln furniture, as well as refractory materials.

It is used in abrasives, high-grade refractory materials, and fine ceramics, etc.

It is used as a reinforcing fiber for composite materials such as resins and metals, and can also be used as an electromagnetic wave absorbing material and heat-resistant material.

It serves as a unidirectional reinforcing material for composite materials, improving various properties. When combined with plastics, metals, and ceramics, it can improve various properties. It can be combined with thermoplastic and thermosetting resins to significantly improve the strength, flexural modulus, thermal conductivity, and wear resistance of plastics. When 15% silicon carbide whiskers are added to PEEK, the thermal conductivity is increased by about 2 times, and the flexural strength of 20% silicon carbide-reinforced polyimide is increased by about 2 times at room temperature, and is the same as the unreinforced case at 250°C. The wear rate is reduced by 17% when 15% silicon carbide is added to epoxy resin.

Kami adunay daghang mga de-kalidad nga pabrika nga adunay lawom nga kooperasyon, nga makahatag kanimo og taas nga kalidad nga mga produkto ug mga presyo sa kompetisyon. Ug makahatag usab kami og mga diskwento alang sa dinaghan nga pagpalit.Ug kami nakigtambayayong sa daghang mga propesyonal nga kompanya sa pagpasa sa kargamento, makahatud sa mga produkto nga luwas ug hapsay sa imong mga kamot. Delivery panahon mao ang mahitungod sa 3-20 ka adlaw human sa pagkumpirma sa pagbayad.

Natural existence

Moissanite in nature exists only in very small amounts in certain types of meteorites, corundum deposits, etc. Most of the silicon carbide currently sold worldwide, including moissanite jewelry, is synthetic.

In 1893, Mosan first discovered the naturally occurring form of silicon carbide in meteorites in Arizona, and in 1905, the material was named Moissanite. [5] But Dr. Mossan's findings were initially questioned because his samples may have been contaminated with the silicon carbide saw blades already on the market at the time. [6]

Silicon carbide is rare on Earth, but common in space. Silicon carbide found in space and meteorites is mostly β-SiC. Analysis of SiC particles found in the Murchison meteorite revealed an unusual isotopic ratio of carbon to silicon, suggesting that the particles originated outside the solar system. [7]

Scale production

Silicon carbide is a kind of carbide accidentally discovered in the laboratory by the American Acheson during the electromelting diamond experiment in 1891. At that time, Acheson was trying to make artificial diamonds, when he heated clay (aluminum silicate) and powdered coke (carbon) in an iron bowl, the formation of blue crystals, which was mistaken for a mixture of diamond, so the name emery. In 1893, Acheson studied the method of industrial smelting silicon carbide, which is often called Acheson furnace, which has been used until now, a resistance furnace with carbon materials as the core body of the furnace, and a mixture of quartz SiO2 and carbon is heated by electricity to generate silicon carbide.

1. Ikaw ba usa ka pabrika o usa ka kompanya sa pamatigayon?

Kami usa ka compnay nga naghiusa sa industriya ug pamatigayon, nga naghatag ug one-stop service.OEM mahimong dawaton.

2. Naghatag ka ba og mga sampol? Libre ba kini o sobra?

Libre nga mga sample.Ang bayad sa kargamento sa sample kinahanglan nga ibayad sa imong kiliran.

3. Aduna ka bay mga sertipiko nga may kalabutan sa pagkontrol sa kalidad?

ISO 9001: 2008 nga sertipikasyon aron masiguro ang kalidad.

4. Unsa ang akong ihatag aron makakuha og kinutlo?

Pls ipahibalo kanamo ang tipo sa produkto nga imong gikinahanglan, gidaghanon sa pag-order, adres ug piho nga mga kinahanglanon. Ang kinutlo himuon alang sa imong pakisayran sa oras.

5. Unsa nga matang sa paagi sa pagbayad ang imong gusto? Unsang matanga sa mga termino ang gidawat?

Gidawat nga Delivery Terms: FOB, CFR, CIF, EXW;

Gidawat nga Bayad nga Salapi:USD;

Gidawat nga Uri sa Pagbayad: T / T, Western Union; Paypal, Trade Assurance.

Pinulongan nga Gisulti: English.

Mga kategoriya sa produkto

-

Apr . 27, 2025Zibo will host the 2025 International Chemical ExpoZibo, a city known for its thriving chemical industry, will host the 2025 Zibo International Chemical Expo from May 16 to May 18, 2025. This highly anticipated event aims to bring together industry leaders, innovators and stakeholders from around the world to explore the latest advancements and trends in the chemical industry.

Apr . 27, 2025Zibo will host the 2025 International Chemical ExpoZibo, a city known for its thriving chemical industry, will host the 2025 Zibo International Chemical Expo from May 16 to May 18, 2025. This highly anticipated event aims to bring together industry leaders, innovators and stakeholders from around the world to explore the latest advancements and trends in the chemical industry. -

Apr . 22, 20252025 Yokohama Cosmetics Raw Materials and Technology ExhibitionYOKOHAMA, Japan – The City of Yokohama is preparing to host the much-anticipated Cosmetics Ingredients & Technologies 2025 from May 14 to May 16, 2025. The premier event is expected to attract industry professionals, innovators and enthusiasts from around the world to showcase the latest advancements in cosmetic ingredients and technologies.

Apr . 22, 20252025 Yokohama Cosmetics Raw Materials and Technology ExhibitionYOKOHAMA, Japan – The City of Yokohama is preparing to host the much-anticipated Cosmetics Ingredients & Technologies 2025 from May 14 to May 16, 2025. The premier event is expected to attract industry professionals, innovators and enthusiasts from around the world to showcase the latest advancements in cosmetic ingredients and technologies. -

Apr . 18, 20252025 India Mumbai Fine Chemicals ExhibitionMUMBAI, India – The bustling metropolis of Mumbai is gearing up to host the much-anticipated Fine Chemicals Expo on April 29-30, 2025. The premier event is expected to attract industry leaders, innovators and stakeholders from across the world to showcase the latest advancements in the fine chemicals sector.

Apr . 18, 20252025 India Mumbai Fine Chemicals ExhibitionMUMBAI, India – The bustling metropolis of Mumbai is gearing up to host the much-anticipated Fine Chemicals Expo on April 29-30, 2025. The premier event is expected to attract industry leaders, innovators and stakeholders from across the world to showcase the latest advancements in the fine chemicals sector.