Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 6

Warning: Undefined array key "file" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Kas . 02, 2024 03:26 Back to list

xanthan gum production process involves bacterial

Xanthan gum is a polysaccharide that plays a crucial role in various industries due to its exceptional thickening and stabilizing properties. The production process of xanthan gum involves a unique fermentation process using the bacterium Xanthomonas campestris. This process not only highlights the fascinating relationship between microorganisms and the food industry but also showcases advanced biotechnological techniques that enhance yield and quality.

Xanthan gum is a polysaccharide that plays a crucial role in various industries due to its exceptional thickening and stabilizing properties. The production process of xanthan gum involves a unique fermentation process using the bacterium Xanthomonas campestris. This process not only highlights the fascinating relationship between microorganisms and the food industry but also showcases advanced biotechnological techniques that enhance yield and quality.

During fermentation, Xanthomonas campestris metabolizes the carbon sources and produces xanthan gum as a byproduct. This process usually occurs under aerobic conditions, where oxygen is supplied to encourage active bacterial growth. The optimal fermentation conditions, including temperature, pH, and agitation speed, are carefully monitored to maximize xanthan gum production. Typically, fermentation can last anywhere from several days to a week, depending on the desired yield and specific production conditions.

xanthan gum production process involves bacterial

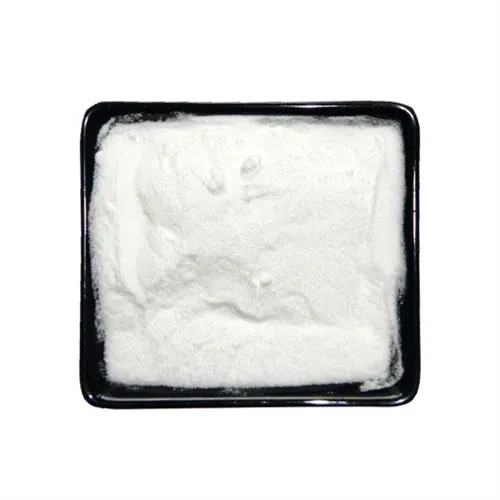

Once the fermentation process is complete, the next step involves harvesting and extracting xanthan gum. The broth containing xanthan gum is subjected to filtration processes to separate the bacterial cells from the polysaccharide. Following filtration, ethanol or isopropanol is often added to the solution to precipitate the xanthan gum, allowing it to be collected easily. The precipitated xanthan gum is then washed, dried, and milled into a fine powder, resulting in the final product ready for various applications.

The versatility of xanthan gum makes it invaluable across multiple sectors, including food, pharmaceuticals, and cosmetics. In the food industry, xanthan gum serves as a thickening agent, stabilizer, and emulsifier, particularly in salad dressings, sauces, and gluten-free products. Its ability to maintain texture and viscosity even in low-fat formulations has led to its widespread use. Additionally, xanthan gum plays a crucial role in the oil and gas industry as a drilling fluid additive, helping to improve viscosity and stability under challenging conditions.

In conclusion, the production of xanthan gum through the fermentation of Xanthomonas campestris is a remarkable example of biotechnological innovation. This process not only underscores the importance of bacteria in the production of valuable compounds but also showcases sustainable practices in industrial manufacturing. As demand for natural and functional ingredients continues to grow, xanthan gum's significance in the food and other industries is likely to increase, driving further research and development in its production techniques.

Latest news

-

Certifications for Vegetarian and Xanthan Gum Vegetarian

NewsJun.17,2025

-

Sustainability Trends Reshaping the SLES N70 Market

NewsJun.17,2025

-

Propylene Glycol Use in Vaccines: Balancing Function and Perception

NewsJun.17,2025

-

Petroleum Jelly in Skincare: Balancing Benefits and Backlash

NewsJun.17,2025

-

Energy Price Volatility and Ripple Effect on Caprolactam Markets

NewsJun.17,2025

-

Spectroscopic Techniques for Adipic Acid Molecular Weight

NewsJun.17,2025