Warning: Undefined array key "file" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

- африқоӣ

- албанӣ

- амхарӣ

- арабӣ

- арманӣ

- озарбойҷонӣ

- баскӣ

- белорус

- бангалӣ

- босниягӣ

- булгорӣ

- каталонӣ

- Себуано

- Хитой

- Чин (Тайван)

- Корсикӣ

- хорватӣ

- чех

- Дания

- Голландия

- англисӣ

- эсперанто

- эстонӣ

- финландӣ

- фаронсавӣ

- фризӣ

- галисия

- гурҷӣ

- олмонӣ

- юнонӣ

- Гуҷаратӣ

- Креоли Гаити

- хауса

- ҳавайӣ

- ибрӣ

- Не

- Миао

- Венгрия

- исландӣ

- игбо

- Индонезия

- ирландӣ

- Италия

- Ҷопон

- ёвонӣ

- каннада

- қазоқӣ

- кхмер

- Руанда

- Корея

- курд

- киргиз

- сил

- лотинӣ

- латыш

- литваӣ

- Люксембург

- македонӣ

- Малгаши

- малайӣ

- малаялам

- малтаӣ

- маори

- маратҳӣ

- муғулӣ

- Мянмар

- непалӣ

- норвегӣ

- норвегӣ

- Окситан

- пашту

- форсӣ

- полякӣ

- португалӣ

- Панҷобӣ

- руминӣ

- русӣ

- самоа

- Гаэли Шотландия

- сербӣ

- англисӣ

- Шона

- Синдӣ

- Сингал

- словакӣ

- словенӣ

- Сомали

- испанӣ

- сунданӣ

- суахили

- шведӣ

- Тагалогӣ

- тоҷикӣ

- тамилӣ

- тоторӣ

- телугу

- тай

- туркӣ

- туркман

- украинӣ

- урду

- уйгур

- узбек

- ветнамӣ

- Уелсӣ

- Кӯмак

- идишӣ

- Ёруба

- Зулу

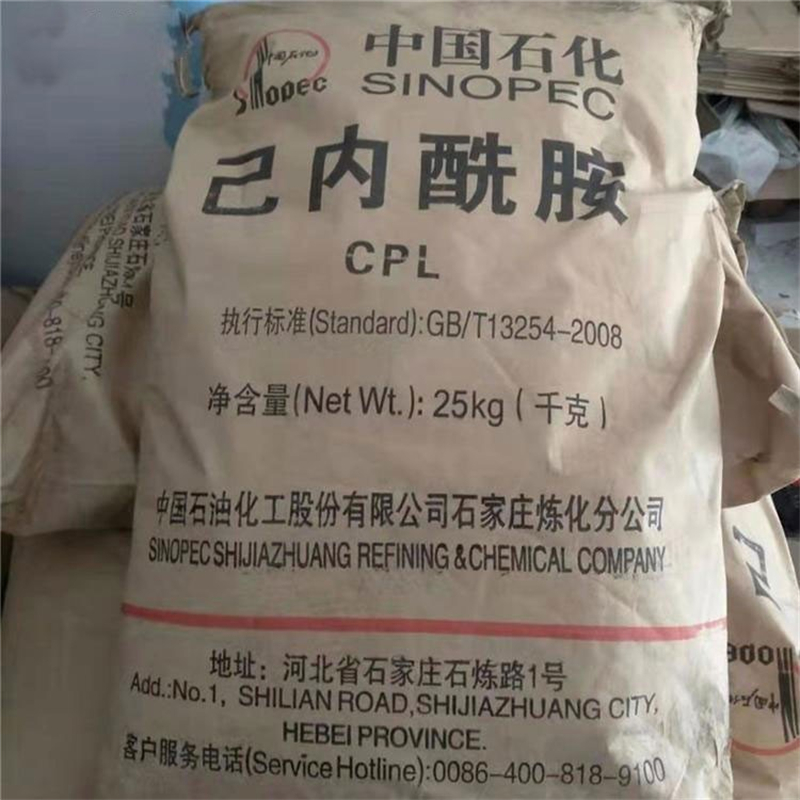

Caprolactam CAS 105-60-2

Caprolactam's molecular formula is C6H11NO, the appearance is white powder or crystal, has an oily feel. Caprolactam is one of the important organic chemical raw materials. Its main use is to generate polyamide slices by polymerization, which can be further processed into polyamide fibers, engineering plastics, and plastic films. Nylon-6 slicing has different application areas with different quality and indexes.

Намоиши маҳсулот

Physical property:

Caprolactam is a white crystal or crystalline powder at room temperature. It is water-absorbing and soluble in solvents such as water, methanol, ethanol, ether, petroleum hydrocarbons, cyclohexene, chloroform and benzene. It has a boiling point of 268.5 degrees Celsius and a freezing point of 69.2 degrees Celsius at 760 mm Hg.

Chemical property:

Caprolactam has good stability at room temperature and pressure, but it is easy to oxidize when it is in contact with oxygen and acidic substances, resulting in pungent odor and toxic gases. Polymerization is easy to occur when exposed to heat.

Caprolactam Application

Textiles and Clothing:

Caprolactam is used in the production of nylon 6, a synthetic fiber widely used in the manufacture of textiles and clothing. Nylon 6 has excellent mechanical properties and durability, suitable for the production of socks, underwear, sportswear, and so on.

Industrial field:

Caprolactam is used in the manufacture of gears, bearings, pipes, medical devices and electrical insulation materials. It is also used as an additive to enhance the hardness, stability, and mechanical properties of plastics, coatings and resins.

Саноати дорусозӣ:

Caprolactam is used in the synthesis of a variety of drugs, such as anti-inflammatory drugs, local anesthetics, biodegradable polymers, and biomedical materials. It is also used in the production of certain drugs such as 6-aminocaproic acid and laurazepone.

Cosmetics and Personal Care Products:

Caprolactam is used to add shine and smoothness to products, such as hair and skin care products.

Rubber industry:

Caprolactam can be used for rubber pretreatment to improve the adhesive force and mechanical properties of rubber.

In addition, caprolactam is also used in other fields, such as paints, adhesives, solvents for high molecular weight polymers, polyurethane crosslinkers, etc. In general, caprolactam is an important chemical raw material, and its application in many fields such as medicine, agriculture, and cosmetics is constantly expanding and deepening.

What is Caprolactam Used For?

Caprolactam, a cyclic amide, plays a critical role in the production of nylon 6, a versatile synthetic polymer widely utilized in various industrial applications. One of the primary caprolactam uses is in the manufacturing of nylon fibers, which are employed in textiles, carpets, and various forms of apparel. The remarkable tensile strength and durability of nylon 6 enhance the quality and longevity of these products, leading to increased demand in the fashion and home furnishings industries.

Another significant application of caprolactam is in the production of engineering plastics. These plastics, known for their excellent mechanical properties, heat resistance, and chemical stability, are essential in automotive, electrical, and consumer goods manufacturing. By incorporating caprolactam-derived nylon 6, manufacturers can produce lightweight and strong components, improving energy efficiency and enhancing performance across a broad spectrum of applications.

In addition to textiles and engineering plastics, caprolactam is also used in the creation of coatings and adhesives. The unique properties of nylon 6 allow for superior adhesion and durability, making it an ideal choice for products requiring strong bonding capabilities. The versatility of caprolactam extends into various sectors, including aerospace and medical applications, where its reliability is paramount.

Moreover, the chemical intermediates derived from caprolactam are vital in synthesizing various compounds, showcasing their central role in the chemical industry. As industries continue to innovate, the demand for caprolactam and its applications will likely grow, underlining its significance in modern manufacturing processes.

In summary, the primary caprolactam use encompasses the production of nylon 6 for textiles, engineering plastics, coatings, and adhesives, making it an indispensable material across multiple industries. The continued evolution and adaptation of caprolactam within various sectors highlight its importance in meeting the demands of contemporary manufacturing.

The factories we cooperate with have large shipments of caprolactam, rapid delivery and fresh production dates. This can help some suppliers and buyers to buy high-quality caprolactam with fresh production date from us. We will not sell products near the expiration date to customers like others, because transportation takes time, so our delivery cycle is usually arranged in 10-15 days, and orders under 10 tons will be shipped within 10 days.

Why Choose Disha Caprolactam Manufacturer in China

In the ever-evolving chemical industry, sourcing high-quality chemical raw materials from reputable manufacturers is paramount. When it comes to caprolactam, a vital component in the production of nylon, Disha stands out as a trusted caprolactam manufacturer in China. Here’s why choosing Disha can be a game-changer for your business.

Expertise and Experience

Disha boasts years of expertise in chemical manufacturing, specifically in caprolactam production. Our advanced manufacturing processes and commitment to quality ensure that our products meet international standards. As a leading caprolactam manufacturer in China, Disha employs the latest technology and skilled professionals to maintain the highest quality levels in our output.

Competitive Pricing

Cost efficiency is a critical factor in any business operation, and Disha understands this need. We offer competitive caprolactam prices without compromising on quality. Our optimized production methods and economies of scale enable us to deliver high-quality caprolactam at prices that help our clients stay ahead in the market. By choosing Disha, you secure not only quality but also value for your investment.

Sustainable Practices

Disha is committed to sustainability and reducing environmental impact. Our manufacturing processes are designed to minimize waste and promote eco-friendly practices. This commitment not only benefits the environment but also aligns with the increasing demand for responsible sourcing in the global market.

Reliable Supply Chain

With Disha as your caprolactam manufacturer in China, you can expect a reliable supply chain. We prioritize timely delivery and efficient logistics, ensuring that your projects remain on schedule. Our strong partnerships with logistics providers enhance our ability to serve clients both domestically and internationally.

In conclusion, choosing Disha as your caprolactam supplier in China guarantees you access to quality products, competitive caprolactam prices, and a commitment to sustainability. Partner with us today to strengthen your business operations and enhance your product offerings.

Хэбэй Диша Import and Export Trade Co., Ltd.

Certificate of Analysis

|

Product Name: |

Капролактам |

|

CAS No. |

105-60-2 |

|

Production quantity |

20000KG |

|

Batch number |

DS20240304 |

|

The date of production & Expiry Date |

2024.03.04 & 2026.03.03 |

|

Inspection date |

2024.03.04 |

|

Адад |

Стандартҳо |

test result |

|

Намуди зоҳирӣ |

off-white to pale yellow crystalline powder |

off-white crystalline powder |

|

identification |

A. Infrared spectrum should conform |

Мутобиқ мекунад |

|

B.should conform |

Мутобиқ мекунад |

|

|

specific rotation |

:+58° ~+64° |

:+61° |

|

loss on drying |

≤3% |

2.30% |

|

PH |

4.5 ~6.5 |

5 |

|

Moisture(water) content |

≤6% |

<4.6% |

|

Absorbance |

≤0,2% |

Мутобиқ мекунад |

|

Absorbance index |

360 ~390 |

Мутобиқ мекунад |

|

Assay of Cefotaxime (calculated on the dried basis) |

≥95% |

99.00% |

|

any individual impurity |

≤1,0% |

0.38% |

|

The sum of all impurities |

≤3% |

1.40% |

|

Bacterial endotoxins |

≤0.2 USP EU/mg |

<0.2 USP EU/mg |

|

Sterility |

Meets the requirements |

Meets the requirements |

|

Detection conclusion |

The product meets the requirements of USP 36 |

|

|

inspector |

Zheng Qiyu |

|

|

quality assurance |

Li Haochen |

|

Environmental hazard:

Caprolactam easily leaches into the soil and pollutes groundwater and nearby streams, posing a threat to the environment.

Health hazards:

caprolactam has a pungent odor, contact may cause minor irritation to the skin, eyes, and mucous membranes, ingestion may have minor toxicity, long-term exposure may lead to headache, dizziness, fatigue, memory loss, sleep disorders and other neurasthenic symptoms.

In addition, caprolactam is an intramolecular shrinkage of ε-aminocaprolic acid H2N(CH2)5COOH, also known as ε-caprolactam. It is mainly used to manufacture other chemicals, such as polyamide slicing (often called polynylon-6 slicing or polynylon-6 slicing) by polymerization, which can be further processed into polyamide fibers, engineering plastics, plastic films, etc.

What is caprolactam?

Caprolactam is a cyclic amide (lactam) that serves as a key precursor in the production of nylon 6, a type of synthetic polymer. It is a white, crystalline solid with a characteristic odor and is primarily produced through the oxidation of cyclohexane. Caprolactam is significant in the textile and plastics industries, where it is used to manufacture fibers, plastics, and resins. Its properties include good chemical resistance and durability, making it suitable for various applications.

What are the appearance and physical characteristics of Caprolactam?

Caprolactam appears as a white powder or crystal with an oily texture. This characteristic appearance is typical for many organic compounds and indicates its high purity and quality. Proper storage conditions are essential to maintain its integrity and effectiveness in applications.

Is Caprolactam safe to handle?

While Caprolactam is routinely used in various industries, it is essential to handle it with appropriate safety measures. Users should adhere to safety guidelines, including wearing protective gear and ensuring proper ventilation in work areas. For detailed safety information, please consult the Material Safety Data Sheet (MSDS) related to this product.

What is the caprolactam process?

Raw Material Preparation

Cyclohexane Oxidation: The process typically starts with cyclohexane, which is oxidized in the presence of air or oxygen to produce cyclohexanol and cyclohexanone (also known as the KA oil).

Amination

The cyclohexanol and cyclohexanone are then subjected to ammoniation, where they react with ammonia. This step often involves the use of a catalyst to facilitate the reaction.

Lactam Formation

The amine produced from the previous step undergoes a cyclization reaction to form caprolactam. This can be achieved by heating the amine under controlled conditions, leading to the formation of the lactam ring.

Purification

The crude caprolactam is then purified through distillation or crystallization to remove impurities and unreacted materials, resulting in high-purity caprolactam suitable for polymerization.

Polymerization

Finally, caprolactam can be polymerized to produce nylon 6, a widely used synthetic fiber and resin.

What is the molecular formula of Caprolactam?

The molecular formula of Caprolactam is C6H11NO. This formula indicates that it consists of six carbon atoms, eleven hydrogen atoms, one nitrogen atom, and one oxygen atom, contributing to its chemical properties as a critical industrial raw material for manufacturing various chemical products.

How should Caprolactam be stored?

Caprolactam should be stored in a cool, dry place away from direct sunlight and incompatible substances. It is crucial to keep the product sealed in its original packaging to prevent contamination. Maintaining optimal storage conditions ensures the quality and effectiveness of Caprolactam over time.

Can Caprolactam be used in food or pharmaceutical applications?

Caprolactam is primarily utilized in industrial applications rather than food or pharmaceutical products. Its usage is regulated, and it is essential to consult relevant industry standards and regulations if considering any application beyond its primary role in nylon production.

Категорияҳои маҳсулот

-

Apr . 27, 2025Zibo will host the 2025 International Chemical ExpoZibo, a city known for its thriving chemical industry, will host the 2025 Zibo International Chemical Expo from May 16 to May 18, 2025. This highly anticipated event aims to bring together industry leaders, innovators and stakeholders from around the world to explore the latest advancements and trends in the chemical industry.

Apr . 27, 2025Zibo will host the 2025 International Chemical ExpoZibo, a city known for its thriving chemical industry, will host the 2025 Zibo International Chemical Expo from May 16 to May 18, 2025. This highly anticipated event aims to bring together industry leaders, innovators and stakeholders from around the world to explore the latest advancements and trends in the chemical industry. -

Apr . 22, 20252025 Yokohama Cosmetics Raw Materials and Technology ExhibitionYOKOHAMA, Japan – The City of Yokohama is preparing to host the much-anticipated Cosmetics Ingredients & Technologies 2025 from May 14 to May 16, 2025. The premier event is expected to attract industry professionals, innovators and enthusiasts from around the world to showcase the latest advancements in cosmetic ingredients and technologies.

Apr . 22, 20252025 Yokohama Cosmetics Raw Materials and Technology ExhibitionYOKOHAMA, Japan – The City of Yokohama is preparing to host the much-anticipated Cosmetics Ingredients & Technologies 2025 from May 14 to May 16, 2025. The premier event is expected to attract industry professionals, innovators and enthusiasts from around the world to showcase the latest advancements in cosmetic ingredients and technologies. -

Apr . 18, 20252025 India Mumbai Fine Chemicals ExhibitionMUMBAI, India – The bustling metropolis of Mumbai is gearing up to host the much-anticipated Fine Chemicals Expo on April 29-30, 2025. The premier event is expected to attract industry leaders, innovators and stakeholders from across the world to showcase the latest advancements in the fine chemicals sector.

Apr . 18, 20252025 India Mumbai Fine Chemicals ExhibitionMUMBAI, India – The bustling metropolis of Mumbai is gearing up to host the much-anticipated Fine Chemicals Expo on April 29-30, 2025. The premier event is expected to attract industry leaders, innovators and stakeholders from across the world to showcase the latest advancements in the fine chemicals sector.