Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 6

Warning: Undefined array key "file" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

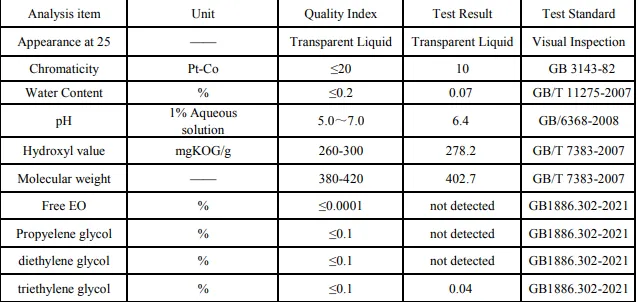

Polyethylene glycol(PEG)

Polyethylene glycol is also known as α-hydrogen-ω-hydroxyl (oxy-1,2-ethylenediyl) polymer, polyethylene oxide (PEO-LS). It is a general term for ethylene glycol polymers with an average molecular weight of about 200 to at least 6000. There are many varieties, such as polyethylene glycol 300 (PEG300), polyethylene glycol 600 (PEG600), polyethylene glycol 20 000 (PEG20M), and the number after PEG indicates the average molecular weight. In addition to the above, the commonly used ones are 1000, 1500, 2000, 4000, 6000, etc. With different average molecular weights, the properties are also different. Colorless and odorless viscous liquid to waxy solid. Soluble in water, ethanol and many other organic solvents. Low vapor pressure. Stable to heat. Ineffective with many chemicals, no hydrolysis, no deterioration. Non-toxic, no obvious irritation to eyes and skin.

The products can be divided into several series such as pharmaceutical grade, cosmetic grade, food grade and industrial grade. [I] The performance of pharmaceutical grade, cosmetic grade and food grade PEG is as follows: Dow Chemical Company first commercialized the production of polyethylene glycol in 1940 and is still a world-recognized leader in the industry. In 1992, Dow Chemical Company's commitment to quality was recognized and became the first American polyethylene glycol manufacturer to obtain ISO9002 certification for production quality systems. The CARBOWAX SENTRY brand polyethylene glycol produced by it has passed the US FDA certification and complies with the standards of the United States Pharmacopoeia (USP), National Formulary (NF), and Food Chemical Codex (FCC). It is widely used in the production of food, pharmaceuticals, feed, personal care products, chemicals and other industries. It is a well-known and trustworthy brand in the industry.

⒈ PEG-400 is most suitable for making soft capsules. Since PEG400 is a liquid, it has wide compatibility with various solvents. It is a good solvent and solubilizer and is widely used in liquid preparations, such as oral solutions, eye drops, etc. When vegetable oil is not suitable as a carrier for active ingredients, PEG is the preferred material. This is mainly because PEG is stable and not easy to deteriorate. The injection containing PEG is very safe and stable when heated to 150 degrees Celsius. In addition, it can be mixed with high molecular weight (PEG) and the mixture has good solubility and good compatibility with drugs.

⒉ PEG-1450, 3350 are most suitable for ointments, suppositories, and creams. Due to their high water solubility and wide melting point range, PEG1450, 3350 can be used alone or mixed to produce a melting point variation range that has a long shelf life and meets the requirements of drug and physical effects. Suppositories using PEG matrix are less irritating than those using traditional oil matrix.

The factories we cooperate with have large shipments of Diethanolamine, rapid delivery and fresh production dates. This can help some suppliers and buyers to buy high-quality Diethanolamine with fresh production date from us. We will not sell products near the expiration date to customers like others, because transportation takes time, so our delivery cycle is usually arranged in 10-15 days, and orders under 10 tons will be shipped within 10 days.

-

图片文字描述1

-

图片文字描述1

The products are non-toxic, non-irritating, slightly bitter, and have good water solubility and good compatibility with many organic components. They have excellent lubricity, moisturizing, dispersibility, adhesives, antistatic agents and softeners, and are widely used in cosmetics, pharmaceuticals, chemical fibers, rubber, plastics, papermaking, paints, electroplating, pesticides, metal processing and food processing industries.

Cell fusion technology mainly uses polyethylene glycol. Polyethylene glycol (PEG) molecules can change the biological membrane structure of various cells, causing the lipid molecules of the plasma membrane at the contact point of the two cells to evacuate and reorganize. Due to the mutual affinity of the bilayer plasma membrane at the interface of the two cells and the surface tension of each other, the cells fuse to form hybrid cells. By culturing the hybrid cells (cytoplasmic hybrids), some special hybrid strains can be obtained.

Uses in Molecular Biology PEG can induce the aggregation of macromolecules in aqueous solution. It has many uses in molecular cloning, including: 1. Precipitating DNA according to molecular size; 2. Precipitating and purifying phage particles; 3. Increasing the binding efficiency of complementary nucleic acid chains during hybridization, blunt-end connection of DNA molecules, and DNA end labeling with T4 polynucleic acid kinase. 4. Fusion of cell or bacterial protoplasts.

Products categories

-

Jun . 06, 2025Xanthan Gum Replacement and Powder InsightsReplacing xanthan gum, understanding xanthan gum gum properties, and selecting high-quality xanthan gum powder are critical considerations for food manufacturers and formulators.

Jun . 06, 2025Xanthan Gum Replacement and Powder InsightsReplacing xanthan gum, understanding xanthan gum gum properties, and selecting high-quality xanthan gum powder are critical considerations for food manufacturers and formulators. -

Jun . 06, 2025Exploring SLES 70 in DepthSles 70, sodium lauryl ether sulfate 70, and sodium lauryl sulfate 70 are among the most widely used surfactants in personal care and cleaning product formulations.

Jun . 06, 2025Exploring SLES 70 in DepthSles 70, sodium lauryl ether sulfate 70, and sodium lauryl sulfate 70 are among the most widely used surfactants in personal care and cleaning product formulations. -

Jun . 06, 2025E1520 Propylene Glycol Uses and Consumption PatternsE1520 propylene glycol, commonly known as propylene glycol, is a versatile chemical compound with extensive applications across multiple industries.

Jun . 06, 2025E1520 Propylene Glycol Uses and Consumption PatternsE1520 propylene glycol, commonly known as propylene glycol, is a versatile chemical compound with extensive applications across multiple industries.