Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 6

Warning: Undefined array key "file" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oct . 18, 2024 00:06 Back to list

Xanthan Gum Utilization in Oil Drilling for Improved Fluid Performance

Xanthan Gum Application in Oil Drilling for Enhanced Fluid Properties

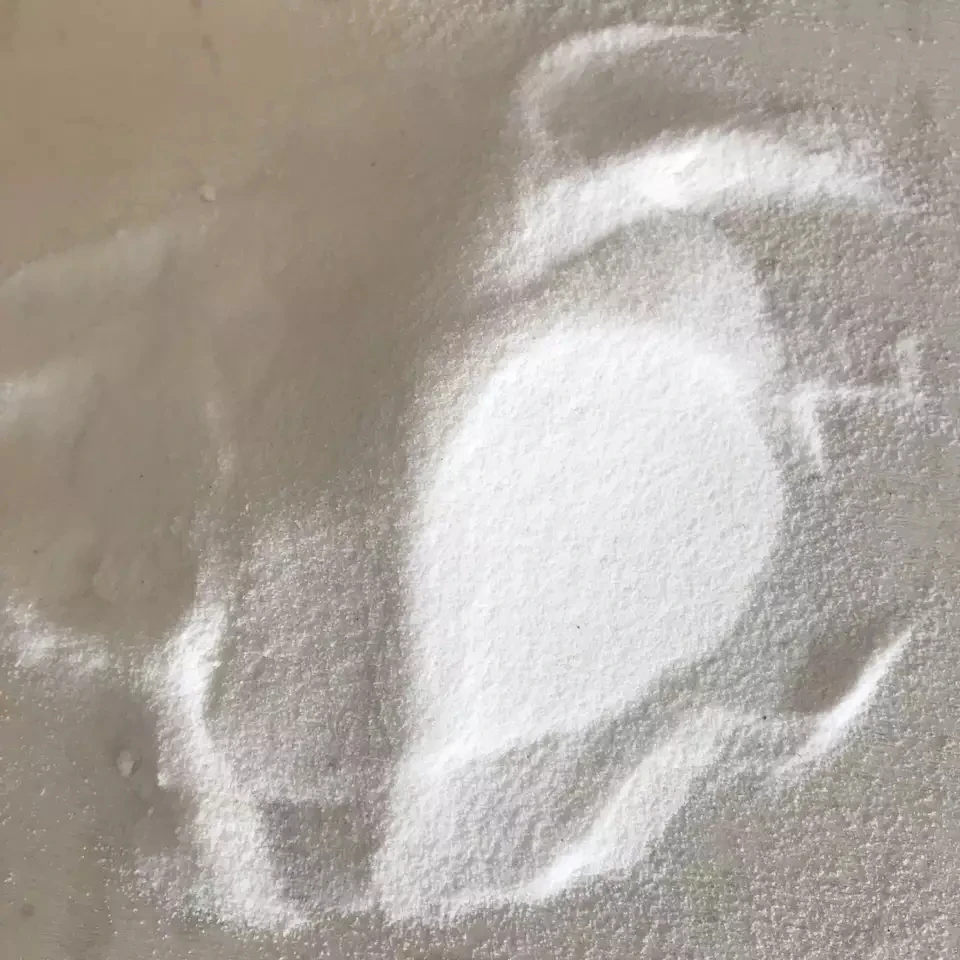

Xanthan gum, a polysaccharide produced by the fermentation of glucose or sucrose by the bacterium Xanthomonas campestris, has found extensive applications across various industries due to its unique properties. Among these applications, its role in the oil drilling sector is particularly noteworthy. The importance of xanthan gum in enhancing the properties of drilling fluids cannot be overstated, as it plays a crucial role in improving efficiency and safety in oil extraction processes.

The Significance of Drilling Fluids

Drilling fluids, also known as muds, are essential in the drilling of boreholes for oil and gas. These fluids serve multiple functions they cool and lubricate the drill bit, remove cuttings from the wellbore, maintain wellbore stability, and prevent formation fluid inflow. The effectiveness of these fluids is greatly influenced by their rheological properties—essentially, their flow behavior—which need to be carefully controlled to adapt to varying geological formations and drilling conditions.

Role of Xanthan Gum in Drilling Fluids

Xanthan gum is primarily utilized as a viscosifier in drilling fluids. By increasing the viscosity of the fluid, xanthan gum enhances its ability to suspend and transport solid materials, such as rock cuttings, to the surface. This property ensures the continuous removal of debris from the drilling site, thereby preventing clogs and ensuring efficient drilling operations.

The addition of xanthan gum to drilling fluids also improves their rheological performance under varying temperatures and pressures. Unlike various other thickening agents, xanthan gum exhibits a remarkable shear-thinning behavior, meaning that it becomes less viscous under high shear conditions—such as during the drilling process—and recovers its viscosity when the shear is reduced. This characteristic is exceptionally beneficial as it allows for easier pumping and handling of the fluid while maintaining sufficient viscosity when needed.

Advantages of Xanthan Gum in Oil Drilling

'xanthan gum application in oil drilling for enhanced fluid'

1. Enhanced Stability Xanthan gum helps maintain the stability of drilling fluids, particularly in high-temperature and high-shear environments, which are common in deep drilling operations. This stability reduces the risk of wellbore collapse and enhances overall drilling safety.

2. Improved Lubrication The increased viscosity provided by xanthan gum contributes to better lubrication of the drill bit. Effective lubrication minimizes wear on the drilling equipment and reduces the likelihood of bit damage, thus extending equipment life and reducing costs.

3. Biodegradability As oil drilling activities face increasing scrutiny regarding environmental impacts, xanthan gum offers an advantage with its biodegradable nature. Unlike synthetic polymers that can persist in the environment, xanthan gum breaks down more easily, making it a more environmentally friendly option for drilling fluids.

4. Cost-Effectiveness Although xanthan gum can be more expensive than some traditional additives, the enhanced performance and reduced downtime it offers can offset these costs. The efficiency gained through improved drilling performance can lead to faster well completion and lower overall operational expenses.

Challenges and Considerations

Despite its advantages, the use of xanthan gum in drilling fluids is not without challenges. One of the primary concerns is its sensitivity to electrolytes, which can reduce its thickening ability. In environments with high salinity or dissolved solids, the effectiveness of xanthan gum may be compromised. Therefore, careful formulation of the drilling fluid is required to optimize the concentration of xanthan gum in conjunction with other additives to ensure maximum performance.

Conclusion

The application of xanthan gum in oil drilling represents a significant advancement in the development of drilling fluids. Its unique properties, including excellent thickening ability, shear-thinning behavior, and biodegradability, make it an invaluable resource in the quest for efficient and environmentally responsible oil extraction. As the oil and gas industry continues to evolve and adapt to new challenges, xanthan gum's role in enhancing fluid properties in drilling operations will likely remain a critical focus for improving operational efficiencies and sustainability.

Latest news

-

Certifications for Vegetarian and Xanthan Gum Vegetarian

NewsJun.17,2025

-

Sustainability Trends Reshaping the SLES N70 Market

NewsJun.17,2025

-

Propylene Glycol Use in Vaccines: Balancing Function and Perception

NewsJun.17,2025

-

Petroleum Jelly in Skincare: Balancing Benefits and Backlash

NewsJun.17,2025

-

Energy Price Volatility and Ripple Effect on Caprolactam Markets

NewsJun.17,2025

-

Spectroscopic Techniques for Adipic Acid Molecular Weight

NewsJun.17,2025