Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 6

Warning: Undefined array key "file" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 05, 2024 21:04 Back to list

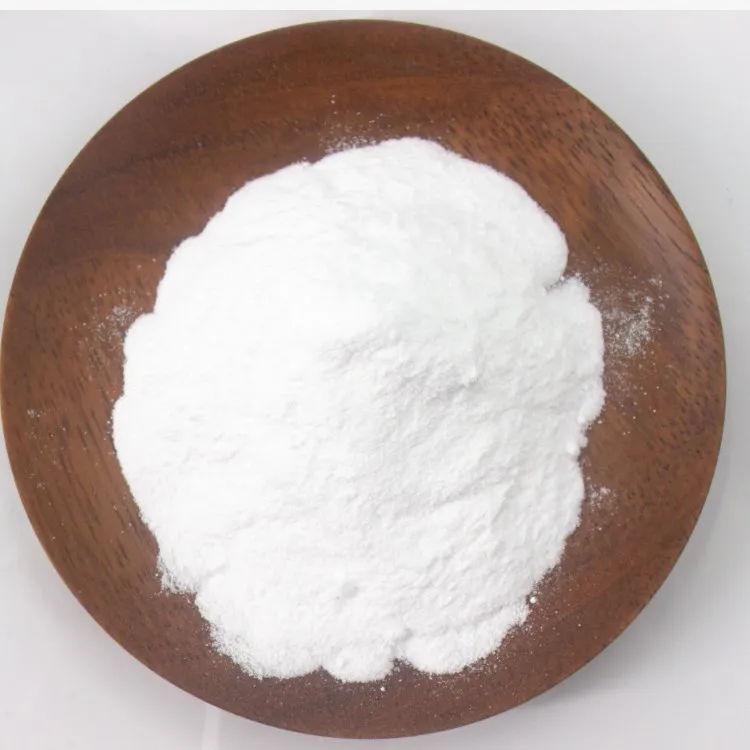

polyethylene glycol and polypropylene glycol

Polyethylene Glycol and Polypropylene Glycol A Comparative Overview

Polyethylene glycol (PEG) and polypropylene glycol (PPG) are two synthetic polymers that have garnered significant attention in various industries due to their versatile properties and applications. Both belong to the family of polyether compounds, yet they exhibit distinct characteristics that make them suitable for different uses.

Polyethylene Glycol Properties and Applications

Polyethylene glycol is a water-soluble polymer synthesized from the polymerization of ethylene oxide. Its molecular weight can vary widely, resulting in PEG compounds that range from a viscous liquid to a waxy solid. This variability allows PEG to be tailored for specific applications, making it a valuable component in pharmaceuticals, cosmetics, and food products.

One of the key properties of PEG is its hydrophilicity, which enables it to form strong hydrogen bonds with water molecules. This characteristic makes PEG an ideal excipient in drug formulation, ensuring better solubility and bioavailability of active pharmaceutical ingredients. Furthermore, because PEG is biologically inert, it is well-tolerated by the human body, which is why it is often used in laxatives, ointments, and even vaccine formulations.

In the cosmetic industry, PEG is utilized as a humectant, emulsifier, and surfactant. Its ability to retain moisture makes it a popular ingredient in skincare products, while its emulsifying properties help stabilize formulations. Additionally, in the food industry, PEG serves as an additive that enhances texture and stability in various food products.

polyethylene glycol and polypropylene glycol

Polypropylene Glycol Properties and Applications

On the other hand, polypropylene glycol is derived from the polymerization of propylene oxide and is characterized by its lower water solubility compared to PEG. PPG’s lower hydrophilicity results in a higher oxidative stability, making it suitable for applications in more demanding environments, such as industrial lubricants and antifreeze formulations.

PPG's non-toxic and biodegradable nature further contributes to its utility in diverse applications, including as a surfactant and dispersant in agriculture and environmental sectors. Its viscosity can be controlled and modified, allowing for the development of products with specific flow characteristics—essential in applications requiring precision, such as in coatings and adhesives.

Comparative Analysis

While both PEG and PPG are versatile and widely used, their differences dictate their suitability for specific applications. PEG’s high water solubility makes it more suitable for pharmaceutical and cosmetic formulations, where interaction with water is crucial. Conversely, PPG’s stability and low water solubility make it preferable in industrial applications where moisture resistance and high-temperature performance are required.

In conclusion, the choice between polyethylene glycol and polypropylene glycol ultimately depends on the specific requirements of the application at hand. Understanding their unique properties not only aids in product formulation but also ensures that industries can leverage these polymers effectively to meet consumer needs. As research advances, we can expect to see even more innovative applications for these essential compounds, further highlighting their importance in modern technology and daily life.

Latest news

-

Certifications for Vegetarian and Xanthan Gum Vegetarian

NewsJun.17,2025

-

Sustainability Trends Reshaping the SLES N70 Market

NewsJun.17,2025

-

Propylene Glycol Use in Vaccines: Balancing Function and Perception

NewsJun.17,2025

-

Petroleum Jelly in Skincare: Balancing Benefits and Backlash

NewsJun.17,2025

-

Energy Price Volatility and Ripple Effect on Caprolactam Markets

NewsJun.17,2025

-

Spectroscopic Techniques for Adipic Acid Molecular Weight

NewsJun.17,2025