Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 6

Warning: Undefined array key "file" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 10, 2024 13:14 Back to list

A Comprehensive Guide to the Adipic Acid Manufacturing Process and Techniques

A Detailed Overview of the Manufacturing Process of Adipic Acid

Adipic acid, a key industrial chemical, is an important precursor for the production of nylon, particularly Nylon 6,6. This diacid is primarily valued for its role in the synthesis of polyamides, elastomers, and various plasticizers. Adipic acid is also utilized in the manufacture of adhesives, coatings, and food additives. The manufacturing processes involved in producing adipic acid are complex and require meticulous attention to detail to ensure efficiency and sustainability. This article presents an in-depth overview of the adipic acid manufacturing process.

Raw Materials

The production of adipic acid primarily begins with two raw materials cyclohexane and nitric acid. Cyclohexane, which can be derived from petroleum, undergoes controlled oxidation to form a mixture of cyclohexanol and cyclohexanone. This mixture is further processed before reacting with nitric acid to produce the desired adipic acid.

Oxidation Process

The first step in the production of adipic acid is the oxidation of cyclohexane. This process typically takes place in the presence of air, where cyclohexane is converted to a mixture of cyclohexanol and cyclohexanone—a process known as air oxidation. The reaction is catalyzed by cobalt or manganese compounds that enhance the reaction rate. The temperature and pressure in the reactor are closely monitored, as they significantly influence the yield and selectivity of cyclohexanol and cyclohexanone.

Nitric Acid Oxidation

The next crucial step is the oxidation of the cyclohexanol and cyclohexanone mixture using nitric acid. This reaction takes place in a reactor at elevated temperatures and pressures. The resulting oxidation reaction forms a complex mixture that includes adipic acid, as well as by-products such as nitrogen oxides and water. The nitrogen oxides can be harmful to the environment, so proper scrubbing and treatment processes are necessary to minimize emissions and comply with environmental regulations.

Crystallization

manufacturing process of adipic acid a detailed overview of ...

Once the oxidation process is complete, the reaction mixture is typically cooled and treated to crystallize the adipic acid. This is often done by adding water or other solvents to the mixture. The adipic acid crystals are then separated from the remaining by-products using filtration or centrifugation.

Purification

The crude adipic acid obtained from crystallization contains impurities that need to be removed to achieve the desired purity level for industrial applications. The purification of adipic acid is usually performed by recrystallization. The crude product is dissolved in a suitable solvent (commonly water or ethanol), heated, and then slowly cooled to allow pure adipic acid crystals to form. This process may be repeated multiple times to enhance the purity of the final product.

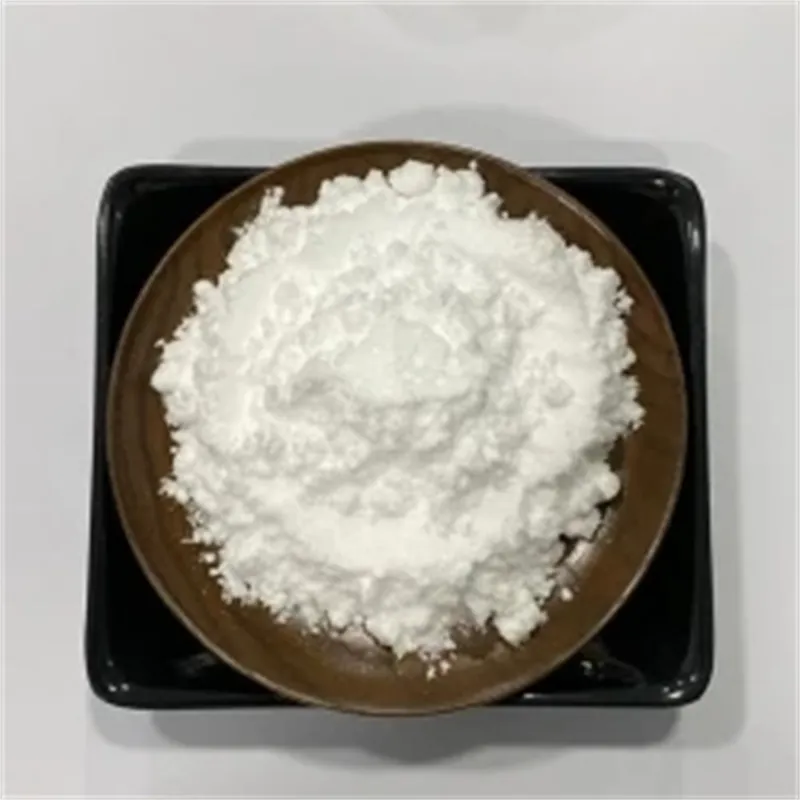

Drying and Packaging

After purification, the adipic acid crystals must be dried to remove any residual solvents or moisture. This is typically performed using rotary vacuum dryers or tray dryers. The dried adipic acid is then ground into a fine powder and packaged for transportation and storage. Proper packaging is essential to prevent contamination and degradation during shipping and handling.

Environmental Considerations

The production of adipic acid, while crucial for various industries, poses environmental challenges, particularly in terms of greenhouse gas emissions and toxic by-products. As a result, many manufacturers are exploring more sustainable production methods. Alternatives, such as bio-based routes using renewable biomass, are being investigated to reduce the environmental footprint of adipic acid production.

Conclusion

In summary, the manufacturing process of adipic acid involves several critical steps including oxidation of cyclohexane, nitric acid oxidation, crystallization, purification, and drying. Given its significance in the production of nylon and other industrial applications, continued advancements in the manufacturing methods—especially those focused on sustainability—are essential for the future of adipic acid production. As industries strive to meet both market demand and environmental standards, innovative solutions will play a key role in shaping the manufacturing landscape of this vital chemical.

Latest news

-

Certifications for Vegetarian and Xanthan Gum Vegetarian

NewsJun.17,2025

-

Sustainability Trends Reshaping the SLES N70 Market

NewsJun.17,2025

-

Propylene Glycol Use in Vaccines: Balancing Function and Perception

NewsJun.17,2025

-

Petroleum Jelly in Skincare: Balancing Benefits and Backlash

NewsJun.17,2025

-

Energy Price Volatility and Ripple Effect on Caprolactam Markets

NewsJun.17,2025

-

Spectroscopic Techniques for Adipic Acid Molecular Weight

NewsJun.17,2025