Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 6

Warning: Undefined array key "file" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Dec . 11, 2024 11:40 Back to list

manufacture of adipic acid

The Manufacture of Adipic Acid Processes and Applications

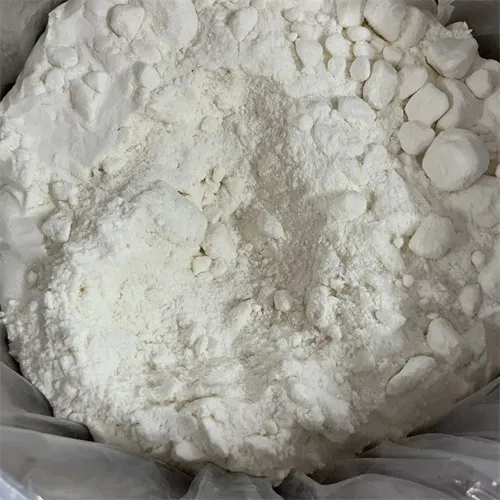

Adipic acid, a colorless crystalline compound, plays a crucial role in various industrial applications, particularly in the production of nylon, plastics, and food additives. Its significance is underscored by a growing demand caused by the expanding markets for synthetic fibers, automotive components, and other polymer-based materials. This article explores the manufacturing processes of adipic acid, its applications, and the environmental implications associated with its production.

Manufacturing Processes

Adipic acid is primarily manufactured through the oxidation of cyclohexanone and cyclohexanol, a process that has been refined over the years to enhance efficiency and reduce environmental impact. The oxidation reaction is typically carried out using nitrogen oxides as catalysts and is facilitated by a variety of oxidizing agents, including air. The general reaction can be depicted as follows

\[ \text{C}_6\text{H}_{10}\text{O} + \text{O}_2 \rightarrow \text{C}_6\text{H}_{10}\text{O}_4 \]

In this reaction, cyclohexanol and cyclohexanone react with oxygen to produce adipic acid along with other byproducts. The key to a successful manufacturing process lies in the careful control of reaction conditions, including temperature, pressure, and reaction time, which helps maximize yield and minimize waste.

Another method for producing adipic acid is through the fermentation of carbohydrates, a more sustainable approach that is gaining traction in the industry. In this biotechnological process, specific strains of microorganisms convert sugars into adipic acid, resulting in a product that is more environmentally friendly compared to traditional fossil fuel-based methods. Although this method is not yet widely adopted on a commercial scale, ongoing research shows promising advancements in production efficiency.

Applications

manufacture of adipic acid

The primary application of adipic acid is in the synthesis of nylon-6,6, a high-performance polymer widely used in textiles, automotive parts, and engineering plastics. The polymerization process involves the condensation of adipic acid with hexamethylenediamine, leading to the formation of nylon, which boasts excellent strength, durability, and resistance to various chemicals.

Beyond nylon production, adipic acid is utilized in the manufacture of various polyurethanes, coatings, and thermoplastic elastomers. It also serves as an acidulant in food products, providing tartness and enhancing flavor profiles. Other applications include the production of hydraulic fluids, lubricants, and as a plasticizer in rubber formulations.

Environmental Considerations

Despite its vast applications, the production of adipic acid poses several environmental challenges. Traditional manufacturing processes, particularly those that rely on fossil fuels, contribute significantly to greenhouse gas emissions, primarily nitrous oxide, a potent greenhouse gas. This has led to increased scrutiny and demand for greener alternatives.

In recent years, the industry has reacted by investing in more sustainable methods of production, such as the aforementioned fermentation process and the implementation of cleaner technologies in existing manufacturing plants. Regulatory pressures and consumer demand for sustainable practices are driving a shift toward the development of eco-friendly adipic acid production methods.

Conclusion

The manufacture of adipic acid is an essential aspect of the chemical industry, with far-reaching implications for various sectors, including textiles, automotive, and food production. As environmental concerns continue to shape industrial practices, the future of adipic acid production will likely see an increased emphasis on sustainable methods that minimize ecological impact while meeting global demand. Continued innovation and research will be pivotal in balancing production efficiency with environmental stewardship, ensuring that adipic acid remains a vital component of modern manufacturing processes.

Latest news

-

Certifications for Vegetarian and Xanthan Gum Vegetarian

NewsJun.17,2025

-

Sustainability Trends Reshaping the SLES N70 Market

NewsJun.17,2025

-

Propylene Glycol Use in Vaccines: Balancing Function and Perception

NewsJun.17,2025

-

Petroleum Jelly in Skincare: Balancing Benefits and Backlash

NewsJun.17,2025

-

Energy Price Volatility and Ripple Effect on Caprolactam Markets

NewsJun.17,2025

-

Spectroscopic Techniques for Adipic Acid Molecular Weight

NewsJun.17,2025