Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 6

Warning: Undefined array key "file" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Lap . 27, 2024 09:17 Back to list

Understanding the Bacterial Production Process of Xanthan Gum for Various Applications

The Xanthan Gum Production Process A Closer Look at Bacterial Fermentation

Xanthan gum, a polysaccharide derived from the fermentation of carbohydrates by the bacterium *Xanthomonas campestris*, has gained significant attention across various industries due to its wide-ranging applications, particularly in the food, cosmetic, and pharmaceutical sectors. This article provides an overview of the xanthan gum production process, highlighting the key stages and the importance of bacterial fermentation.

Origin of Xanthan Gum

Discovered in the 1960s, xanthan gum has quickly moved from being a laboratory curiosity to a staple ingredient in modern food products. It serves as a thickening agent, stabilizer, and emulsifier, providing desired textures and consistency to products like salad dressings, sauces, dairy products, and gluten-free baked goods. Beyond the food industry, xanthan gum is used in cosmetics for its emulsifying properties and in pharmaceuticals to improve the viscosity and stability of liquid formulations.

The Role of Bacterial Fermentation

At the heart of xanthan gum production is bacterial fermentation, a process involving the conversion of sugars into polysaccharides by microorganisms. In this case, *Xanthomonas campestris*, a gram-negative bacterium, plays a crucial role. It is known for its ability to thrive in various environments and for its efficient metabolism of carbohydrates.

Step-by-Step Production Process

1. Selection of Raw Materials The production of xanthan gum begins with the selection of appropriate raw materials, primarily carbohydrates, which can come from sources like corn syrup, molasses, or other sugars. These sugars serve as the primary carbon source for the *Xanthomonas campestris* bacteria.

2. Inoculation and Fermentation Once the raw materials are prepared, they are inoculated with a culture of *Xanthomonas campestris*. This inoculation is typically done in a controlled environment, such as a fermenter that ensures optimal conditions for bacterial growth, including appropriate temperature, pH, and aeration. The fermentation period usually lasts between 48 to 72 hours, during which bacteria metabolize the sugars and produce xanthan gum.

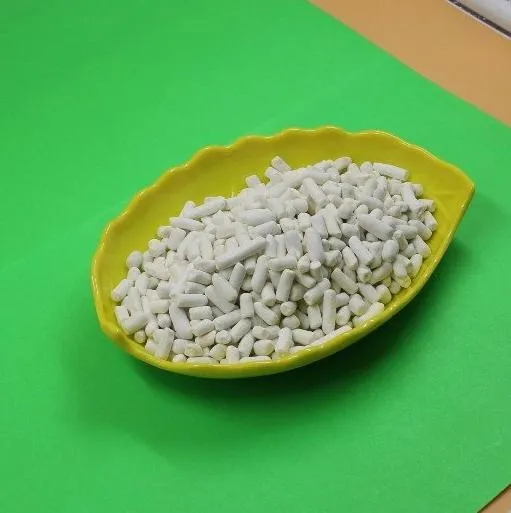

xanthan gum production process involves bacterial ...

3. Harvesting After fermentation, the xanthan gum produced is in a slurry form, mixed with other fermentation by-products. The next step involves harvesting the xanthan gum through processes such as centrifugation or filtration, which separates the gum from the liquid fermentation medium.

4. Precipitation and Isolation The xanthan gum can be further purified by precipitating it with isopropyl alcohol or ethanol. This helps in isolating xanthan gum from other impurities and by-products from the fermentation process. The resultant product is then washed, dried, and milled into a fine powder.

5. Quality Control Before xanthan gum is packaged and distributed, it undergoes rigorous quality control tests to ensure it meets the necessary standards for purity, viscosity, and microbiological safety. This part of the process is vital, as consistency in quality is crucial for its application across various industries.

6. Packaging Once it passes quality control, xanthan gum is packaged in airtight containers to maintain its stability and prevent moisture absorption, which can affect its performance.

Applications and Impact

The versatility of xanthan gum has made it an indispensable ingredient in many formulations. In the food industry, it enables products to maintain consistency and stability, enhancing the eating experience. In personal care products, it helps achieve desired textures and enhances product performance. In pharmaceuticals, xanthan gum improves the delivery of active ingredients, making medications more effective.

Conclusion

The bacterial fermentation process that leads to the production of xanthan gum exemplifies the intersection of microbiology and industrial applications. As demand for natural thickeners and stabilizers continues to rise, understanding and optimizing the production techniques involved in xanthan gum production will be crucial in meeting the needs of various industries. Overall, xanthan gum's unique properties and the sustainable methods of its production promise a bright future for this remarkable biopolymer.

Latest news

-

Certifications for Vegetarian and Xanthan Gum Vegetarian

NewsJun.17,2025

-

Sustainability Trends Reshaping the SLES N70 Market

NewsJun.17,2025

-

Propylene Glycol Use in Vaccines: Balancing Function and Perception

NewsJun.17,2025

-

Petroleum Jelly in Skincare: Balancing Benefits and Backlash

NewsJun.17,2025

-

Energy Price Volatility and Ripple Effect on Caprolactam Markets

NewsJun.17,2025

-

Spectroscopic Techniques for Adipic Acid Molecular Weight

NewsJun.17,2025