Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 6

Warning: Undefined array key "file" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ಡಿಸೆ . 02, 2024 01:28 Back to list

'xanthan gum application in oil drilling for enhanced fluid'

Xanthan Gum Application in Oil Drilling for Enhanced Fluid Properties

In the oil and gas industry, the efficiency and effectiveness of drilling operations have always been of paramount importance. One crucial aspect that significantly influences the success of these operations is the drilling fluid, commonly referred to as drilling mud. Drilling fluids serve multiple purposes, including lubricating the drill bit, stabilizing the borehole, and carrying the cuttings to the surface. Among various additives used to enhance the performance of drilling fluids, xanthan gum has emerged as a preferred choice due to its unique properties and benefits.

What is Xanthan Gum?

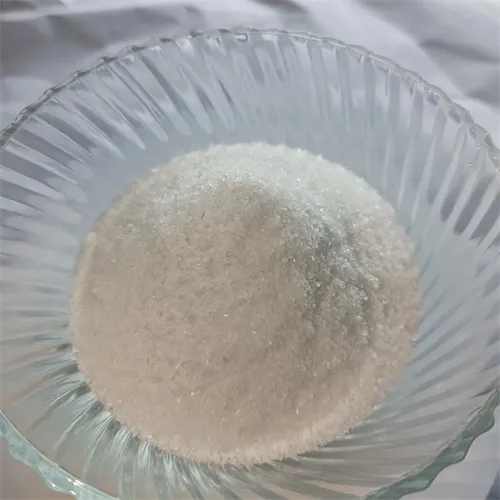

Xanthan gum is a natural polysaccharide produced through the fermentation of the bacterium *Xanthomonas campestris*. It is widely recognized for its ability to stabilize and thicken water-based fluids. Its unique molecular structure allows it to form a highly viscous solution even at low concentrations, making it an ideal additive in various industrial applications, including food, cosmetics, and pharmaceuticals. In the context of oil drilling, xanthan gum enhances the rheological properties of drilling fluids, providing improved performance under the high-pressure and high-temperature conditions typically encountered in drilling operations.

Enhancing Fluid Properties

The primary role of xanthan gum in drilling fluids is to modify their rheology, which refers to the way these fluids flow and deform under stress. This is crucial for maintaining a stable borehole during drilling operations. When added to water-based drilling mud, xanthan gum increases viscosity, which enhances the fluid's ability to suspend and transport solid materials, such as rock cuttings, from the drill bit to the surface. This not only aids in the cleaning of the borehole but also reduces the risks of clogging and stuck pipe incidents.

Importantly, xanthan gum exhibits pseudoplastic behavior, meaning that its viscosity decreases under high shear rates—often present during drilling. When drilling occurs, the high shear forces experienced within the drill bit allow the fluid to flow easily, while its standing viscosity remains high when at rest. This property ensures efficient drilling and effective hole cleaning, making xanthan gum a valuable additive for maintaining optimal fluid dynamics in varying operational conditions.

Temperature Stability

'xanthan gum application in oil drilling for enhanced fluid'

Another significant advantage of xanthan gum is its thermal stability. In deep or geothermal drilling, where temperatures can exceed 400°F (204°C), the stability of drilling fluids is critical. Xanthan gum retains its thickening properties at elevated temperatures, ensuring that the drilling fluid maintains adequate viscosity and performance even in extreme conditions. This characteristic reduces the likelihood of fluid breakdown, enhancing the overall reliability of drilling operations.

Environmental Considerations

In today’s environmentally conscious world, the impact of drilling fluids on the environment cannot be overlooked. Xanthan gum is produced from natural sources and is considered biodegradable and non-toxic, making it a favorable choice compared to synthetic polymers. Its application in drilling can contribute to greener operations while still ensuring that the fluid properties meet the rigorous demands of oil extraction.

Economic Benefits

Incorporating xanthan gum into drilling fluid formulations can also yield economic benefits. Enhanced drilling efficiency can lead to reduced operational costs, shorter drilling times, and minimized wear and tear on equipment. Moreover, by improving the performance of the drilling mud, xanthan gum can help oil and gas companies minimize the risks of drilling-related issues such as wellbore instability or fluid loss, thereby reducing unplanned expenditures.

Conclusion

The application of xanthan gum in oil drilling represents a crucial development in the optimization of drilling fluids. By significantly enhancing rheological properties, maintaining viscosity at high temperatures, and offering environmental benefits, xanthan gum plays a vital role in ensuring successful drilling operations. As the industry continues to evolve and face new challenges, the adaptability and efficiency of xanthan gum make it an invaluable component in the quest for more effective and sustainable drilling solutions. Embracing natural additives like xanthan gum not only addresses technical demands but also aligns with the broader goals of reducing the environmental footprint of oil and gas extraction efforts. Moving forward, the oil and gas industry can benefit greatly from continued research and development in the application of xanthan gum and similar biodegradable materials in drilling practices.

Latest news

-

Certifications for Vegetarian and Xanthan Gum Vegetarian

NewsJun.17,2025

-

Sustainability Trends Reshaping the SLES N70 Market

NewsJun.17,2025

-

Propylene Glycol Use in Vaccines: Balancing Function and Perception

NewsJun.17,2025

-

Petroleum Jelly in Skincare: Balancing Benefits and Backlash

NewsJun.17,2025

-

Energy Price Volatility and Ripple Effect on Caprolactam Markets

NewsJun.17,2025

-

Spectroscopic Techniques for Adipic Acid Molecular Weight

NewsJun.17,2025