Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 6

Warning: Undefined array key "file" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Hebei Yize Trade Center Co., LTD.!

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ಜನ . 17, 2025 05:34 Back to list

Polypropylene

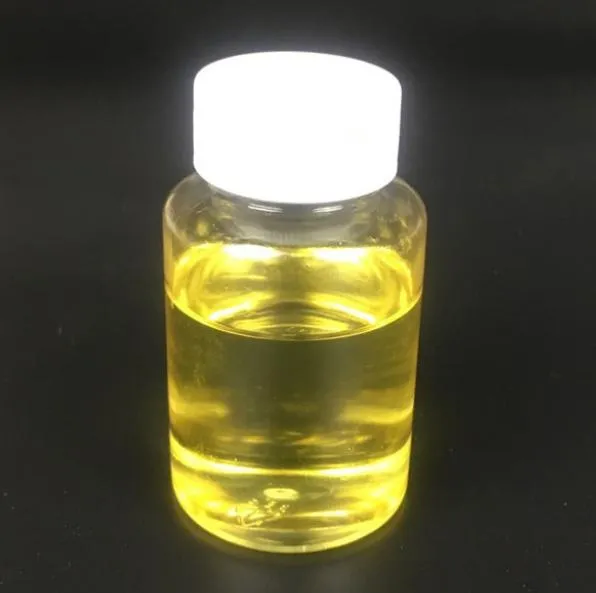

Polyethylene glycol (PEG) and polypropylene glycol (PPG) are critical components in countless industrial and consumer products due to their versatile properties and broad applicability. These polyethers are not just chemical compounds; they are integral to creating products that we encounter daily.

Trustworthiness in products containing PEG and PPG also involves transparently addressing potential health impacts. Regulatory bodies such as the FDA in the United States or the European Medicines Agency ensure that PEGs used in consumable products meet stringent safety criteria. Similarly, the environmental impact of PPG, especially regarding degradation and bioaccumulation, is of ongoing study, ensuring that industries employ these compounds responsibly. From a product experience perspective, end-users might unknowingly encounter PEG and PPG in daily life, from toothpaste providing the perfect viscosity to antifreeze ensuring automobiles operate smoothly in varying temperatures. These compounds significantly enhance the user experience by optimizing the product's functionality and lifespan. Understanding PEG and PPG's roles creates a landscape of continuous exploration and innovation—one where chemistry meets everyday life. Researchers are now investigating more sustainable production methods and alternatives to minimize ecological footprints while maintaining performance benchmarks. As the journey of polyethylene glycol and polypropylene glycol evolves, it stays committed to enhancing product quality and fostering a sustainable future. This duality—from enhancing product effectiveness to championing eco-friendly alternatives—marks the future of chemical manufacturing. Thus, polyethylene glycol and polypropylene glycol remain pivotal in modern chemistry, shaping products that redefine convenience and sustainability.

Trustworthiness in products containing PEG and PPG also involves transparently addressing potential health impacts. Regulatory bodies such as the FDA in the United States or the European Medicines Agency ensure that PEGs used in consumable products meet stringent safety criteria. Similarly, the environmental impact of PPG, especially regarding degradation and bioaccumulation, is of ongoing study, ensuring that industries employ these compounds responsibly. From a product experience perspective, end-users might unknowingly encounter PEG and PPG in daily life, from toothpaste providing the perfect viscosity to antifreeze ensuring automobiles operate smoothly in varying temperatures. These compounds significantly enhance the user experience by optimizing the product's functionality and lifespan. Understanding PEG and PPG's roles creates a landscape of continuous exploration and innovation—one where chemistry meets everyday life. Researchers are now investigating more sustainable production methods and alternatives to minimize ecological footprints while maintaining performance benchmarks. As the journey of polyethylene glycol and polypropylene glycol evolves, it stays committed to enhancing product quality and fostering a sustainable future. This duality—from enhancing product effectiveness to championing eco-friendly alternatives—marks the future of chemical manufacturing. Thus, polyethylene glycol and polypropylene glycol remain pivotal in modern chemistry, shaping products that redefine convenience and sustainability.

Next:

Latest news

-

Certifications for Vegetarian and Xanthan Gum Vegetarian

NewsJun.17,2025

-

Sustainability Trends Reshaping the SLES N70 Market

NewsJun.17,2025

-

Propylene Glycol Use in Vaccines: Balancing Function and Perception

NewsJun.17,2025

-

Petroleum Jelly in Skincare: Balancing Benefits and Backlash

NewsJun.17,2025

-

Energy Price Volatility and Ripple Effect on Caprolactam Markets

NewsJun.17,2025

-

Spectroscopic Techniques for Adipic Acid Molecular Weight

NewsJun.17,2025