Warning: Undefined array key "file" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

HYDROXYETHYL CELLULOSE HEC

HEC is a nonionic cellulose derivative that dissolves readily in water, either cold or hot. It is made from natural macromolecular material cellulose through a series of chemical processing. It is used to produce solutions having a wide range of viscosity. Such solutions are pseudoplastic, that is, they vary in viscosity depending upon the amount of stress applied.

HEC-E

Biostable grade HEC-E give powerful, stable thickening in both interior and exterior paints. A creamy in-can stability, excellent water resistance and a good rheology profile. At the same time, it serves as a protective colloid in emulsion polymerization. Also, it's produced with a special process that gives superior biostability to product and this process doesn't make any difference in the chemical and physical property.

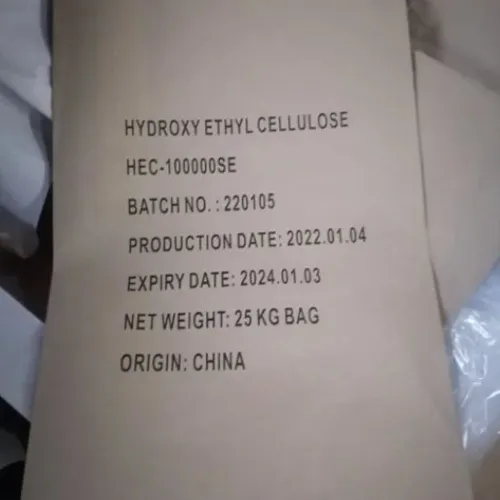

Product display

(NMP) N Methyl 2 Pyrrolidone Solvent Suppliers & Manufacturers & Wholesalers & Factory & Exporters & Producers.

1. Brand: Sinobio

2. Origin: China

3. Delivery time: One week

4. Annual supply capacity: 2000 Tons/Year

5. Purity: ≥99.9%

6. CAS No.: 872-50-4

- High Thickening Effects

Biostable grade HEC-E provides the latex paints especially high PVA paints with excellent coating performance. When the paint is thick paste, no flocculation will occur.

Biostable grade HEC-E has higher thickening effects, so can reduce the dosage, improve the cost-effectiveness of formulation, and enhance the washing resistance of paints.

- Excellent Rheological Properties

The aqueous solution of HEC is a non-Newtonian system, and the properties of the solution are called thixotropy.

In the stationary state, after the product is completely dissolved, the coating system can maintain the best thickening condition and can-opening state.

In the dumping state, the system can keep a moderate viscosity, making products with excellent fluidity, and not spatter.

During brushing and roller coating, the product is easy to spread on the substrate, so convenient for construction, and meanwhile, has good spatter resistance.

Finally, after the coating of paint is completed, the viscosity of the system will immediately get restored, and the paint will immediately produce sagging property.

- Excellent Rheological Properties

The aqueous solution of HEC is a non-Newtonian system, and the properties of the solution are called thixotropy.

In the stationary state, after the product is completely dissolved, the coating system can maintain the best thickening condition and can-opening state.

In the dumping state, the system can keep a moderate viscosity, making products with excellent fluidity, and not spatter.

During brushing and roller coating, the product is easy to spread on the substrate, so convenient for construction, and meanwhile, has good spatter resistance.

Finally, after the coating of paint is completed, the viscosity of the system will immediately get restored, and the paint will immediately produce sagging property.

We have many high-quality factories with deep cooperation, which can provide you with high quality products and competitive prices. And we can also give discounts for bulk purchases.And we cooperate with many professional freight forwarding companies, can deliver products safely and smoothly to your hands. Delivery time is about 3-20 days after confirmation of payment.

| Gram mole substitution (m.s) | Moisture (%) | Insolubility (%) | Transmittance (2%) | NDJ-1 rotary viscosity meter, mpa.s 2% solution,20°C | ||

| Viscosity | Spindle No | rpm | ||||

| 1.8-2.0 | <6 | <0.5 | ≥80 | <100 | 1 | 30 |

| 1.8-2.0 | <6 | <0.5 | ≥80 | 4000~7000 | 3 | 12 |

| 1.8-2.0 | <6 | <0.5 | ≥80 | 8000~12000 | 3 | 6 |

| 1.8-2.0 | <6 | <0.5 | ≥80 | 13000~17000 | 3 | 6 |

| 1.8-2.0 | <6 | <0.5 | ≥80 | 18000~22000 | 4 | 12 |

| 1.8-2.0 | <6 | <0.5 | ≥80 | 26000~34000 | 4 | 12 |

| 1.8-2.0 | <6 | <0.5 | ≥80 | 36000~44000 | 4 | 12 |

| 1.8-2.0 | <6 | <0.5 | ≥80 | 3500~4500 | 3 | 12 |

| 1.8-2.0 | <6 | <0.5 | ≥80 | 5000~6000 | 3 | 1 |

Hydroxyethyl cellulose (HEC)

Hydroxyethyl cellulose is developed and produced by our company for many years. Hydroxyethyl cellulose is a kind of uniform and efficient non-ionic water-soluble polymer. Two products hpy30000s and hpy50000s with different viscosity range are introduced, which are suitable for different fields. Hpy30000s and hpy50000s are mainly used for emulsion paint and hpy50000s for stone paint.

Main quality performance

Versatility: it can be used in different emulsion systems and pH conditions.

Excellent color paste and pigment compatibility

Good water retention

Good color mixing viscosity stability

Good storage stability

Better low foaming and transparency

Features and uses

Hydroxyethyl cellulose (HEC) is a kind of nonionic cellulose ether, which is made from natural polymer cellulose by a series of chemical processes. It is a kind of odorless, tasteless and nontoxic white powder or particle, which can be dissolved in cold water to form a transparent viscous solution, and the dissolution is not affected by pH value. It has the characteristics of thickening, adhesion, dispersion, emulsification, film-forming, suspension, adsorption, surface activity, water retention and salt resistance.

Connect hydroxyethyl cellulose can be widely used in water-based coating, construction mortar, oil drilling, synthetic resin, ceramic industry, medicine, food, textile, agriculture, cosmetics, tobacco, ink, paper daily chemistry and other fields.

Physical and chemical properties:

1, This product is white or yellowish odorless, odorless, tasteless and easy to flow powder, which can be dissolved in cold water and hot water. Generally speaking, the insoluble pH value in most organic solvents changes less in the range of 2-12, but the viscosity decreases beyond this range. The HEC after surface treatment disperses in cold water and does not agglomerate. The dissolution rate is relatively fast. It generally takes about 15min to slowly increase the viscosity.

2. 100 mesh screening rate ≥ 99%; softening temperature: 135-140 ºC; surface density: 0.35-0.61g/ml; decomposition temperature: 205-210 ºC; slow combustion rate; equilibrium moisture content: 23 ºC, 6% at 50% RH, 9% at 84% RH. (RH is relative humidity).

Dissolution method:

Dissolved in water:

Slowly add HEC into the water with violent agitation until it is completely dissolved. If all materials are added, it will be difficult to dissolve

Application Fields:

_______________________________________________________________________________

|

Types of Uses |

Specific Applications |

Properties Utilized |

|

Adhesives |

Wallpaper adhesives |

Thickening and lubricity |

|

Binders |

Welding rods |

Water-binding and extrusion aid |

|

Paints |

latex paint |

Thickening and protective colloid |

|

Cosmetics&detergent |

Hair conditioners |

Thickening |

Products categories

-

Apr . 27, 2025Zibo will host the 2025 International Chemical ExpoZibo, a city known for its thriving chemical industry, will host the 2025 Zibo International Chemical Expo from May 16 to May 18, 2025. This highly anticipated event aims to bring together industry leaders, innovators and stakeholders from around the world to explore the latest advancements and trends in the chemical industry.

Apr . 27, 2025Zibo will host the 2025 International Chemical ExpoZibo, a city known for its thriving chemical industry, will host the 2025 Zibo International Chemical Expo from May 16 to May 18, 2025. This highly anticipated event aims to bring together industry leaders, innovators and stakeholders from around the world to explore the latest advancements and trends in the chemical industry. -

Apr . 22, 20252025 Yokohama Cosmetics Raw Materials and Technology ExhibitionYOKOHAMA, Japan – The City of Yokohama is preparing to host the much-anticipated Cosmetics Ingredients & Technologies 2025 from May 14 to May 16, 2025. The premier event is expected to attract industry professionals, innovators and enthusiasts from around the world to showcase the latest advancements in cosmetic ingredients and technologies.

Apr . 22, 20252025 Yokohama Cosmetics Raw Materials and Technology ExhibitionYOKOHAMA, Japan – The City of Yokohama is preparing to host the much-anticipated Cosmetics Ingredients & Technologies 2025 from May 14 to May 16, 2025. The premier event is expected to attract industry professionals, innovators and enthusiasts from around the world to showcase the latest advancements in cosmetic ingredients and technologies. -

Apr . 18, 20252025 India Mumbai Fine Chemicals ExhibitionMUMBAI, India – The bustling metropolis of Mumbai is gearing up to host the much-anticipated Fine Chemicals Expo on April 29-30, 2025. The premier event is expected to attract industry leaders, innovators and stakeholders from across the world to showcase the latest advancements in the fine chemicals sector.

Apr . 18, 20252025 India Mumbai Fine Chemicals ExhibitionMUMBAI, India – The bustling metropolis of Mumbai is gearing up to host the much-anticipated Fine Chemicals Expo on April 29-30, 2025. The premier event is expected to attract industry leaders, innovators and stakeholders from across the world to showcase the latest advancements in the fine chemicals sector.