Warning: Undefined array key "file" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Hebei Yize Trade Center Co., LTD.!

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jun . 15, 2024 18:12 Back to list

Here are 10 short phrases similar to menthol process in English 1. Menthol manufacturing 2. Menthol production line 3. Menthol refinement process 4. Menthol extraction method 5. Menthol synthesis pro

Menthol Process A Comprehensive Guide

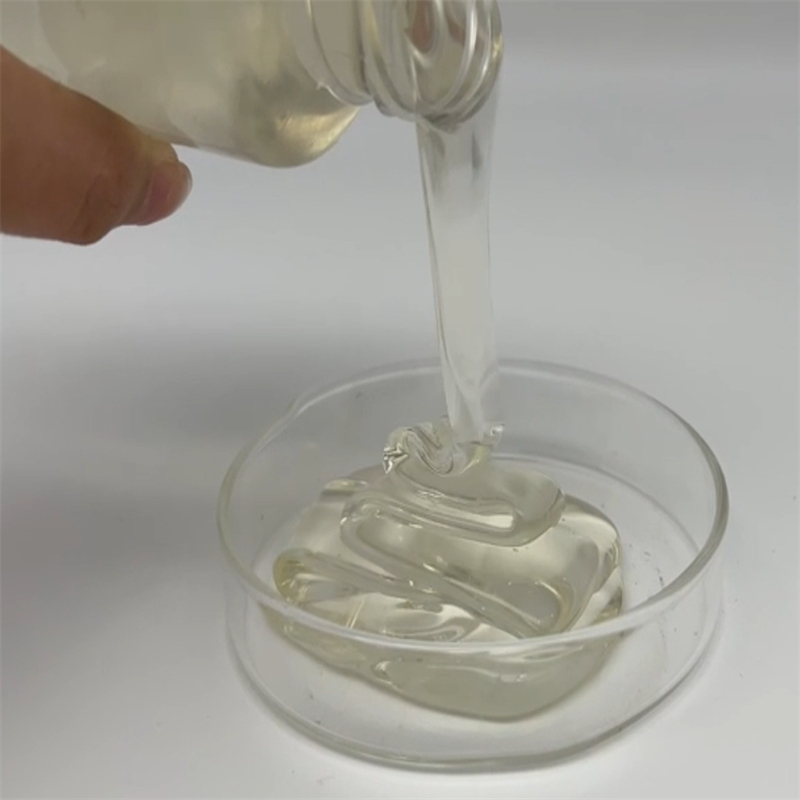

Menthol, a naturally occurring compound found in mint plants, is widely used in various consumer products due to its refreshing and cooling properties. The menthol process, which involves the extraction and purification of menthol from mint oil, is a crucial step in the production of menthol-based products. In this article, we will provide a comprehensive guide to the menthol process, including its history, key steps, and environmental considerations.

History of Menthol Process

The use of menthol dates back thousands of years, with ancient civilizations using it for medicinal and religious purposes. However, it was not until the 19th century that the process of extracting menthol from mint oil was developed. This breakthrough was achieved by German chemist Wilhelm Heinrich Haarmann and his business partner Johann Friedrich Wilhelm Adolf von Baeyer, who patented the first method for producing pure menthol in 1872. Since then, the menthol process has undergone continuous improvement, leading to more efficient and cost-effective methods of production.

Key Steps of the Menthol Process

The menthol process consists of several key steps, including

1. Mint Oil Extraction Mint oil is extracted from mint plants through a process called steam distillation. The plant material is heated with steam, which releases the essential oils contained within the plant. The resulting vapor is then condensed back into liquid form, separating the oil from the water.

2. Purification The crude mint oil obtained from the distillation process contains impurities such as water, waxes, and other compounds. These impurities are removed through a series of purification steps, including acidification, neutralization, and filtration.

3

3 3

3

3

3 menthol process. Fractionation The purified mint oil is then fractionated to separate menthol from other components such as menthone and menthyl esters. This is typically done using a technique called vacuum distillation, which allows for the separation of compounds with different boiling points.

4. Crystallization The final step in the menthol process is crystallization, where menthol is separated from the remaining oil by cooling the mixture to a temperature below its melting point. The resulting crystals are then collected and dried to obtain pure menthol.

Environmental Considerations

The menthol process has significant environmental impacts, particularly in terms of resource consumption and waste generation. Mint plants require large amounts of water for cultivation, and the distillation process generates significant amounts of wastewater containing volatile organic compounds (VOCs) and other pollutants. Additionally, the disposal of menthol production waste can also have negative environmental impacts.

To mitigate these environmental concerns, many manufacturers are adopting more sustainable practices in their menthol production processes. This includes using water-efficient cultivation techniques, implementing closed-loop distillation systems to reduce wastewater generation, and exploring alternative waste treatment options.

In conclusion, the menthol process is a complex and multi-step process that involves the extraction and purification of menthol from mint oil. While the process has been refined over time, there are still opportunities to improve its environmental sustainability. By adopting more sustainable practices, manufacturers can help ensure that the production of menthol-based products remains a responsible and environmentally friendly industry.

menthol process. Fractionation The purified mint oil is then fractionated to separate menthol from other components such as menthone and menthyl esters. This is typically done using a technique called vacuum distillation, which allows for the separation of compounds with different boiling points.

4. Crystallization The final step in the menthol process is crystallization, where menthol is separated from the remaining oil by cooling the mixture to a temperature below its melting point. The resulting crystals are then collected and dried to obtain pure menthol.

Environmental Considerations

The menthol process has significant environmental impacts, particularly in terms of resource consumption and waste generation. Mint plants require large amounts of water for cultivation, and the distillation process generates significant amounts of wastewater containing volatile organic compounds (VOCs) and other pollutants. Additionally, the disposal of menthol production waste can also have negative environmental impacts.

To mitigate these environmental concerns, many manufacturers are adopting more sustainable practices in their menthol production processes. This includes using water-efficient cultivation techniques, implementing closed-loop distillation systems to reduce wastewater generation, and exploring alternative waste treatment options.

In conclusion, the menthol process is a complex and multi-step process that involves the extraction and purification of menthol from mint oil. While the process has been refined over time, there are still opportunities to improve its environmental sustainability. By adopting more sustainable practices, manufacturers can help ensure that the production of menthol-based products remains a responsible and environmentally friendly industry.

3

3

3

3 menthol process. Fractionation The purified mint oil is then fractionated to separate menthol from other components such as menthone and menthyl esters. This is typically done using a technique called vacuum distillation, which allows for the separation of compounds with different boiling points.

4. Crystallization The final step in the menthol process is crystallization, where menthol is separated from the remaining oil by cooling the mixture to a temperature below its melting point. The resulting crystals are then collected and dried to obtain pure menthol.

Environmental Considerations

The menthol process has significant environmental impacts, particularly in terms of resource consumption and waste generation. Mint plants require large amounts of water for cultivation, and the distillation process generates significant amounts of wastewater containing volatile organic compounds (VOCs) and other pollutants. Additionally, the disposal of menthol production waste can also have negative environmental impacts.

To mitigate these environmental concerns, many manufacturers are adopting more sustainable practices in their menthol production processes. This includes using water-efficient cultivation techniques, implementing closed-loop distillation systems to reduce wastewater generation, and exploring alternative waste treatment options.

In conclusion, the menthol process is a complex and multi-step process that involves the extraction and purification of menthol from mint oil. While the process has been refined over time, there are still opportunities to improve its environmental sustainability. By adopting more sustainable practices, manufacturers can help ensure that the production of menthol-based products remains a responsible and environmentally friendly industry.

menthol process. Fractionation The purified mint oil is then fractionated to separate menthol from other components such as menthone and menthyl esters. This is typically done using a technique called vacuum distillation, which allows for the separation of compounds with different boiling points.

4. Crystallization The final step in the menthol process is crystallization, where menthol is separated from the remaining oil by cooling the mixture to a temperature below its melting point. The resulting crystals are then collected and dried to obtain pure menthol.

Environmental Considerations

The menthol process has significant environmental impacts, particularly in terms of resource consumption and waste generation. Mint plants require large amounts of water for cultivation, and the distillation process generates significant amounts of wastewater containing volatile organic compounds (VOCs) and other pollutants. Additionally, the disposal of menthol production waste can also have negative environmental impacts.

To mitigate these environmental concerns, many manufacturers are adopting more sustainable practices in their menthol production processes. This includes using water-efficient cultivation techniques, implementing closed-loop distillation systems to reduce wastewater generation, and exploring alternative waste treatment options.

In conclusion, the menthol process is a complex and multi-step process that involves the extraction and purification of menthol from mint oil. While the process has been refined over time, there are still opportunities to improve its environmental sustainability. By adopting more sustainable practices, manufacturers can help ensure that the production of menthol-based products remains a responsible and environmentally friendly industry. Latest news

-

Zibo will host the 2025 International Chemical Expo

NewsApr.27,2025

-

2025 Yokohama Cosmetics Raw Materials and Technology Exhibition

NewsApr.22,2025

-

2025 India Mumbai Fine Chemicals Exhibition

NewsApr.18,2025

-

Nanjing will host the 2025 Yangtze River Delta International Chemical Industry Expo and the National Chemical Industry Conference

NewsApr.15,2025

-

2025 Seoul Chemical and Fine Chemicals Exhibition

NewsApr.08,2025

-

The upcoming IESD 2025: Shanghai International Surfactant and Detergent Exhibition

NewsApr.01,2025