- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Set . 01, 2024 21:56 Back to list

Xanthan Gum Production from Corn for Industrial Applications

Making Xanthan Gum from Corn for Various Industrial Applications

Xanthan gum, a polysaccharide produced by the fermentation of carbohydrates, is widely used across various industries, notably in food, pharmaceuticals, and cosmetics, due to its excellent thickening and stabilizing properties. Derived primarily from the fermentation of corn, this versatile gum has increasingly gained attention for its multifunctional capabilities, which are instrumental in product formulation and enhancement.

The process of making xanthan gum from corn begins with the selection of high-quality corn starch, which serves as the primary carbohydrate source. After cleaning and milling the corn, the starch is extracted and subjected to enzymatic hydrolysis to convert it into simpler sugars. This step is crucial because the fermentation bacteria, specifically *Xanthomonas campestris*, utilize these sugars to produce xanthan gum.

Next, the prepared sugar solution is cultivated under controlled conditions. Inoculation with *Xanthomonas campestris* occurs, and the culture is maintained in a bioreactor with optimal temperature, pH, and aeration. The bacteria ferment the sugars, leading to the production of xanthan gum, which is excreted into the fermentation broth. This fermentation process typically takes several days and is carefully monitored to maximize yield and purity.

making xanthan gum from corn for various industrial and

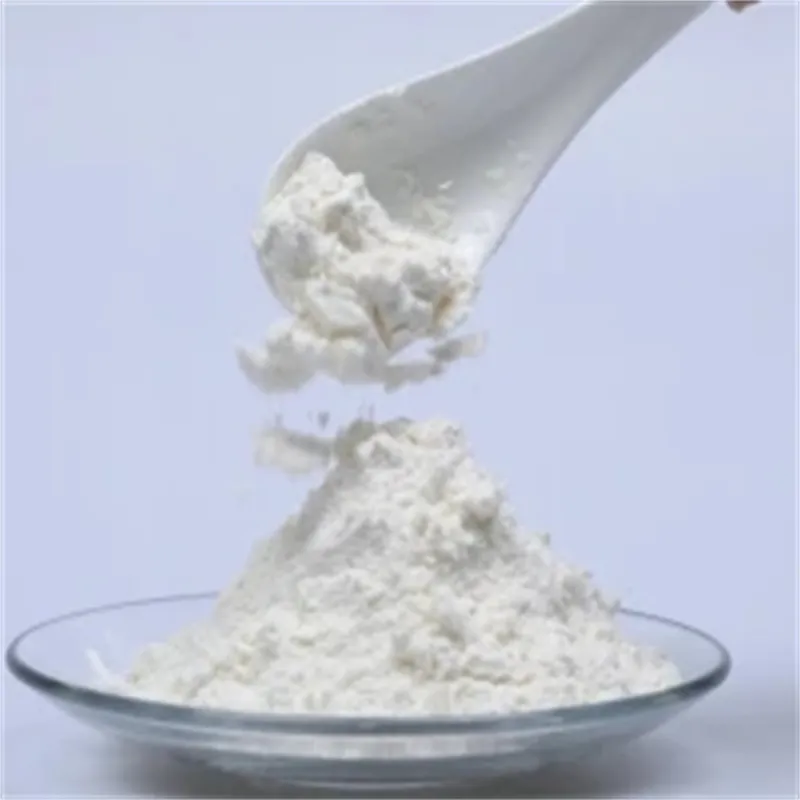

Once fermentation is complete, the xanthan gum must be recovered from the broth. This is usually achieved through precipitation using isopropyl alcohol or ethanol, which separates the xanthan gum from the liquid. The precipitated gum is then washed and dried to obtain a powder form. This xanthan gum can be further milled to adjust particle size based on industry requirements.

Xanthan gum's unique properties make it suitable for a wide range of applications. In the food industry, it acts as a thickening agent in salad dressings, sauces, and dairy products, enhancing texture and stability. In pharmaceuticals, xanthan gum serves as a suspending agent for liquid formulations and as a binder in tablets. Moreover, in cosmetics, it provides a smooth consistency in creams and lotions, improving the overall user experience.

The growing interest in sustainable and natural ingredients has also led to an increased demand for xanthan gum derived from corn. As consumers become more health-conscious, the use of xanthan gum as a natural thickener aligns well with trends toward clean label products. Additionally, the utilization of corn—a renewable resource—embraces principles of sustainability and environmental responsibility.

In conclusion, the production of xanthan gum from corn not only fulfills a significant role in various industrial applications but also showcases the intersection of biotechnology and sustainable practices. As industries continue to evolve, xanthan gum is poised to remain an essential ingredient, contributing to innovation and improvement in product quality across multiple sectors.

Latest news

-

O-Vanillin: A rising star in the flavors and fragrances industry

NewsMay.23,2025

-

2025 Brazil Sao Paulo Cosmetics Exhibition

NewsMay.20,2025

-

2025 European Fine Chemicals Exhibition in Germany

NewsMay.13,2025

-

2025 New York Cosmetics Ingredients Exhibition

NewsMay.07,2025

-

Zibo will host the 2025 International Chemical Expo

NewsApr.27,2025

-

2025 Yokohama Cosmetics Raw Materials and Technology Exhibition

NewsApr.22,2025