Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 6

Warning: Undefined array key "file" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

Warning: Undefined array key "title" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1198/header.php on line 7

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Ліст . 25, 2024 12:04 Back to list

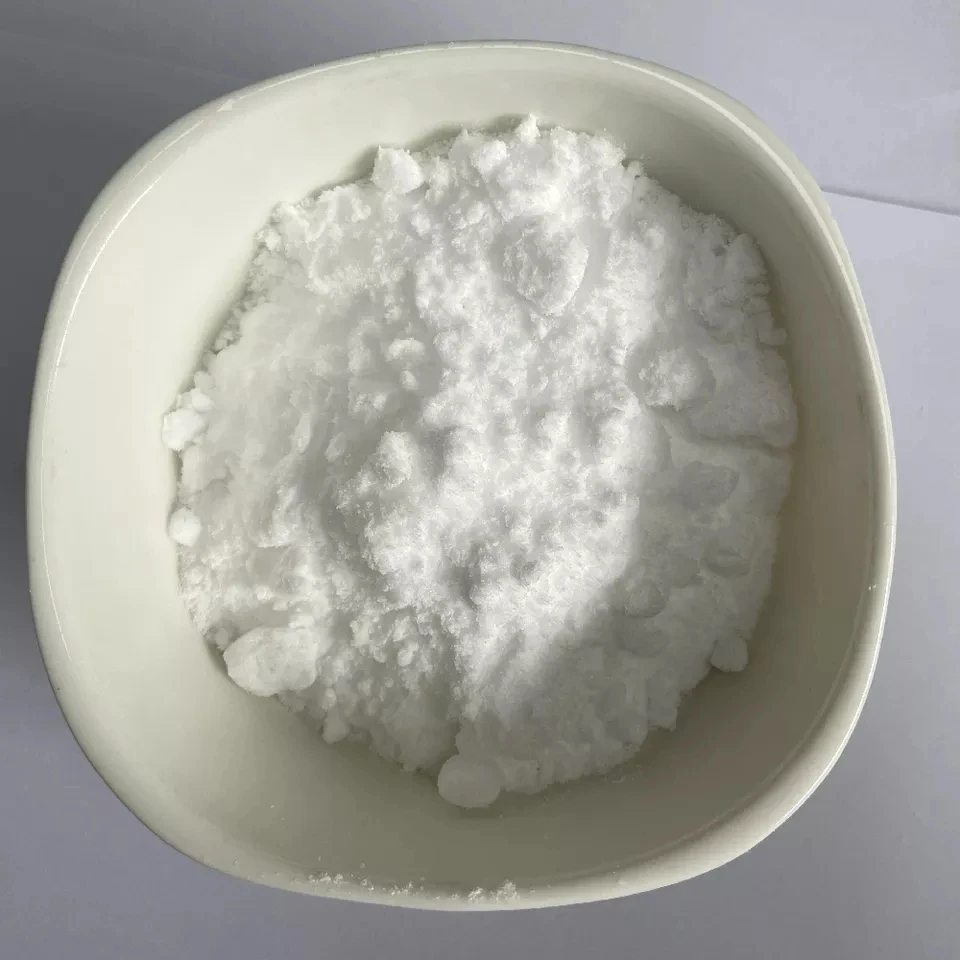

xylitol process

The Xylitol Process An Overview

Xylitol, a sugar alcohol naturally found in many fruits and vegetables, has gained recognition as a low-caloric sweetener with a multitude of health benefits. Understanding the process of xylitol production is essential for appreciating its widespread use in sugar-free products and its role in promoting dental health.

The Nature of Xylitol

Xylitol is a five-carbon sugar alcohol, categorized as a polyol, which is utilized as a sugar substitute due to its sweet taste, comparable to that of sucrose. Unlike regular sugar, xylitol has a lower glycemic index, making it a favored choice for those managing blood sugar levels, such as diabetics. Additionally, xylitol has been found to help in preventing dental cavities by inhibiting the growth of bacteria that cause tooth decay.

Sources of Xylitol

The primary sources of xylitol are plant materials, especially hardwood trees like birch and certain types of corn. The extraction and production process begins with these raw materials, which are rich in hemicellulose, a complex carbohydrate made up of xylose. The extraction involves several steps that transform xylose into pure xylitol.

The Xylitol Production Process

1. Raw Material Preparation The process begins with harvesting and milling the source material to create a fine powder. The wood, typically birch or cornstalks, is processed to release xylose through a series of chemical treatments.

2. Hydrolysis The milled biomass undergoes hydrolysis, which involves breaking down the hemicellulose to release xylose. This is typically achieved using acids or enzymes that convert polysaccharides into monosaccharides.

xylitol process

3. Fermentation The xylose extracted from the hydrolysis stage is then subject to fermentation. During this process, specific strains of yeast or bacteria are used to ferment xylose into xylitol. The fermentation conditions, including temperature and pH, are carefully controlled to optimize yield.

4. Separation and Purification After fermentation, the mixture contains not only xylitol but also various byproducts. The next phase involves separating xylitol from these impurities. This is commonly done through filtration, followed by crystallization. The resulting product is a pure form of xylitol, which can be used in various applications.

5. Drying and Packaging The final steps involve drying the xylitol to ensure that it has the right moisture content and packaging it for distribution. Modern facilities use advanced technology to maintain the quality and stability of xylitol during this phase.

Applications of Xylitol

Xylitol's versatility has led to its incorporation into a range of products. Most notably, it is used in sugar-free gum, mints, and toothpaste. Its ability to promote salivation helps neutralize acids in the mouth, counteracting cavity-causing bacteria. Additionally, xylitol is utilized in various food products as a low-calorie sweetener, providing a guilt-free alternative to traditional sugars.

Health Benefits and Considerations

While xylitol is generally recognized as safe for consumption, it is essential to use it judiciously. Overconsumption can lead to gastrointestinal discomfort, including bloating and diarrhea, particularly in individuals unaccustomed to it. Moreover, xylitol is highly toxic to dogs, making it crucial for pet owners to be vigilant about products containing this sweetener.

Conclusion

The xylitol process involves intricate steps including hydrolysis, fermentation, and purification, transforming natural plant materials into a health-promoting sweetener. With a wide array of applications, from oral care to food products, xylitol stands out for its unique benefits over traditional sugars. As the world continues to seek healthier alternatives, xylitol is poised to remain a popular choice in the realm of sweeteners. Understanding its production process not only appreciates its utility but also emphasizes the importance of sustainable practices in the food industry.

Latest news

-

Certifications for Vegetarian and Xanthan Gum Vegetarian

NewsJun.17,2025

-

Sustainability Trends Reshaping the SLES N70 Market

NewsJun.17,2025

-

Propylene Glycol Use in Vaccines: Balancing Function and Perception

NewsJun.17,2025

-

Petroleum Jelly in Skincare: Balancing Benefits and Backlash

NewsJun.17,2025

-

Energy Price Volatility and Ripple Effect on Caprolactam Markets

NewsJun.17,2025

-

Spectroscopic Techniques for Adipic Acid Molecular Weight

NewsJun.17,2025