Hebei Yize Trade Center Co., LTD.!

Jan . 13, 2025 12:24 Back to list

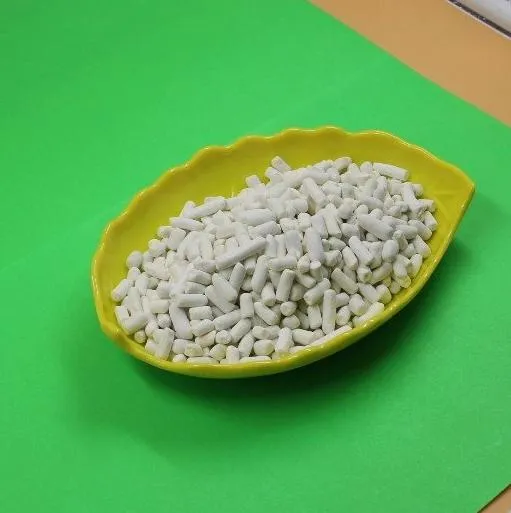

adipic acid

Adipic acid plays a crucial role in modern industrial applications, prominently used in the production of nylon as well as a variety of other products. Its significance in product manufacturing makes understanding its production process invaluable for those in chemical engineering and industrial chemistry.

In discussing the adipic acid manufacturing process, it is imperative to highlight the authoritative nature of safety and regulatory compliance. One cannot overlook the stringent assessment of environmental impacts, primarily from the release of nitrous oxide—a potent greenhouse gas—during production. To address this, various mitigation techniques are being adopted within the industry, including advanced catalyst systems and gas recovery processes, underscoring the industry's commitment to sustainable practices and trustworthiness in production operations. Furthermore, within the broader chemical market, adipic acid derives its authority not only from its primary use in nylon 6,6 production but also its versatility in creating polyurethane foams, plasticizers, and lubricants. This diverse applicability necessitates a deep understanding of its chemical properties and the ability to tailor the production process to meet specific industry demands. Cultivating expertise in the adipic acid process accords significant competitive advantages, particularly for those equipped with hands-on experience and knowledge of cutting-edge production technologies. Engineers and chemists working in this domain are continuously innovating, employing sophisticated methodologies and quality improvement frameworks to enhance process efficiency and sustainability. In conclusion, the adipic acid process is not just a technical endeavor but an evolving landscape of innovation, sustainability practices, and an embodiment of scientific authority. Those steering the course of its production are not only tasked with meeting present demands but are also at the forefront of pioneering future possibilities, ensuring its ongoing relevance in an ever-changing industrial ecosystem.

In discussing the adipic acid manufacturing process, it is imperative to highlight the authoritative nature of safety and regulatory compliance. One cannot overlook the stringent assessment of environmental impacts, primarily from the release of nitrous oxide—a potent greenhouse gas—during production. To address this, various mitigation techniques are being adopted within the industry, including advanced catalyst systems and gas recovery processes, underscoring the industry's commitment to sustainable practices and trustworthiness in production operations. Furthermore, within the broader chemical market, adipic acid derives its authority not only from its primary use in nylon 6,6 production but also its versatility in creating polyurethane foams, plasticizers, and lubricants. This diverse applicability necessitates a deep understanding of its chemical properties and the ability to tailor the production process to meet specific industry demands. Cultivating expertise in the adipic acid process accords significant competitive advantages, particularly for those equipped with hands-on experience and knowledge of cutting-edge production technologies. Engineers and chemists working in this domain are continuously innovating, employing sophisticated methodologies and quality improvement frameworks to enhance process efficiency and sustainability. In conclusion, the adipic acid process is not just a technical endeavor but an evolving landscape of innovation, sustainability practices, and an embodiment of scientific authority. Those steering the course of its production are not only tasked with meeting present demands but are also at the forefront of pioneering future possibilities, ensuring its ongoing relevance in an ever-changing industrial ecosystem.

Latest news

-

Certifications for Vegetarian and Xanthan Gum Vegetarian

NewsJun.17,2025

-

Sustainability Trends Reshaping the SLES N70 Market

NewsJun.17,2025

-

Propylene Glycol Use in Vaccines: Balancing Function and Perception

NewsJun.17,2025

-

Petroleum Jelly in Skincare: Balancing Benefits and Backlash

NewsJun.17,2025

-

Energy Price Volatility and Ripple Effect on Caprolactam Markets

NewsJun.17,2025

-

Spectroscopic Techniques for Adipic Acid Molecular Weight

NewsJun.17,2025